Sintering for production of shock absorbers

In modern machine-building an actively developing technology is a production of sintered powders and using those powders to produce different parts and units, so called metal ceramic parts, which in translation from English means literally “sintered parts”. The name comes from the specifics of technology.

Application in manufacturing of shock absorbers

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining.

Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces.

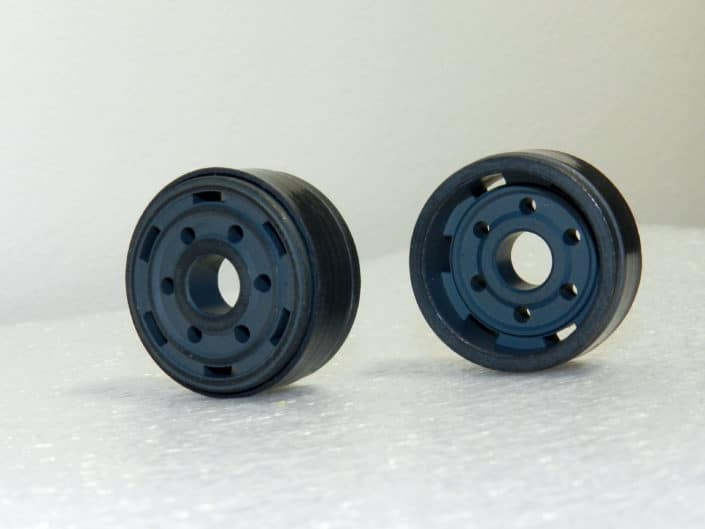

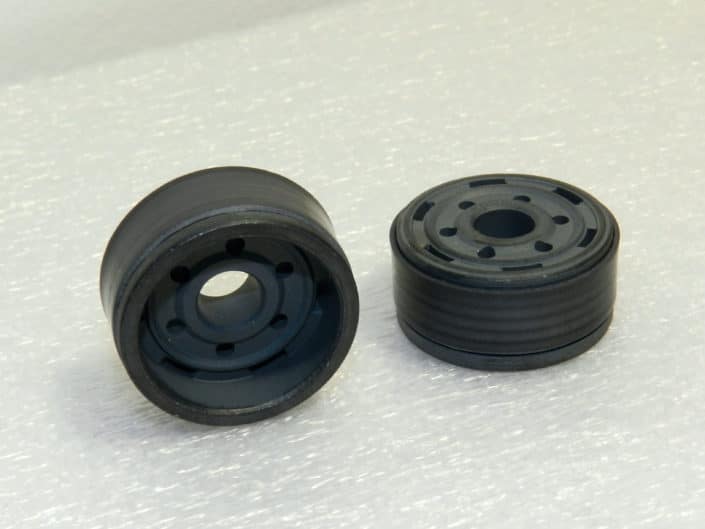

Most important elements of shock absorbers are: piston, seat valve, rod guide. It is very important for those parts to have precise dimensions. Sintering easily allows to meet those targets. Besides, companies producing automotive parts using this technology are able to produce any kind of sintered piston exactly according to the order of the manufacturer of vehicles or repair companies with required batches. Rod guides have especially complicated shape. For this parts, sintering allows to make production easier, reduce cost price and provide perfect accuracy of dimensions.

Application of this technology in production of shock absorbers allows to provide stability and durability of the parts and their work. It gives an opportunity to automotive manufacturers and service centers to provide safety of operation of the vehicle.