To support the success of our customers

PRECISION

All measuring equipment and tools are calibrated regularly in order to secure the high accuracy of measurements.

Anchor studless chains.

Round link chains for continuous conveyors

Round link chains for hoisting machines

Chains for lifting mechanisms.

Welded round link chains

Round medium and long link chains

Special-purpose round link chains

Hardened chains for fishing industry

Round long link chains.

Our main manufacturing of chains are anchor studless chains, chains for lifting mechanisms, hardened chains, trawl chains and fork-shaped chains.

As a rule, steel (alloyed, high-alloyed, carbonaceous, etc., depending on the function of a chain), iron, metal alloys are used as a material.

There are two manufacturing processes:

The simplicity in design, high operational reliability and reasonable price of the round link chain explain why it is so popular.

Another advantage is a diverse assortment that includes the following types of chains.

Depending on the strength:

By the pitch against the thickness of a rod:

Depending on the accuracy of manufacturing:

Round link chains have a wide scope of applications:

An anchor studless chain is a constituent part of an anchor gear and serves to connect the anchor to the hull. However, today anchor studless chains are used not only in the fleet, but also for the needs of ocean oil platforms, floating docks, landing stages, barges, and other similar areas. Anchor studless chains are applied in many other economic sectors: mining and metallurgy, forestry and fishing, in agriculture, if the chains are subjected to heavy loads during operational use.

The anchor studless chain consists of a whole range of components, usually they are the first shot, several intermediate shots (the number depends on the length of a chain cable), the final (bending) shot and an end shackle, all of the components are joined together by Kenter links.

The anchor studless chain consists of high-strength forged or welded links and studs located in the middle. This construction eliminates even the slightest deformation of the chain under tensile loading.

The production of long chains (up to 350 m) is carried out by connecting 25-meter pieces of shots with the help of special detachable links. Small caliber chains (11-13 mm) are usually not divided into shots and produced solid.

The components of an anchor chain: common stud link, enlarged stud link, Kenter link, swivel, end shackles.

The chains of this type are applied in metallurgy, machine building, cement making, timber industry, agriculture, rigging, and also in individual farming. Welded round link chains are made of iron, steel (low-carbon, alloyed and high-alloyed), brass and other alloys. Finished chains can be tumbled, painted (with lacquer or enamels) or galvanized.

Lifting and hauling chains are an indispensable tool for moving large loads, rigging, and other similar operations. The strength of such chains is almost triple the one of metal cables with the same diameter. Lifting and hauling chains are traditionally used in conveyors, escalators, bucket elevators, coal-mining machines, machinery with motor and hand drive, various branches of animal husbandry, timber, oil, and fishing industries.

All products that are manufactured for conveyors and transporters undergo durability tests by modeling an applied dynamic load. The enterprise undergoes regular verifications and attestations by technological supervision agencies and has certificates of product conformity with the safety requirements. The manufacturer produces chains and components for rotary kilns by using flash welding in compliance with the requirements of European norms and standards, according to the technology developed in conjunction with our partners.

Why Us?

Our company manufactures only high-quality products. Besides it, we manufacture our products meeting the requirements of ISO 1704-91 (DSTU 3074-95, GOST 228-95), etc. Our technological equipment and developments allow us to manufacture products with the warranty period that significantly exceeds requirements and with an extended service life, even in case of intensified operational use and low temperatures.

Chain manufacturing company have good contacts with a lot of active shipbuilding and ship repair enterprises. We cooperate with them successfully meeting our obligations.

We compete successfully on the European market, in the segment of chains for offshore oil platforms. French, American, and British consumers purchase mining chains.

PRECISION

All measuring equipment and tools are calibrated regularly in order to secure the high accuracy of measurements.

CERTIFICATION

Positive verifications, conducted by customers and independent certificate companies, are another evidence of our work efficiency.

COMPETITIVE PRICE

We will find a way to provide a competitive price on the market.

QUALITY ASSURANCE

We involve independent expert organizations which control quality according to our customers’ wishes.

MANUFACTURING EXPERIENCE

We do the planning and designing in order to create the most economical product.

SUPPORT

Experience in manufacturing technologies enables us to provide comprehensive consultations on technical matters with customers.

Anchor studless chains

Anchor studless chains are produced according to ISO 1704-91 (DSTU 3074-95, GOST 228-95), and according to agreed customer drawings. They are made of carbon and alloy steel of 1, 2 and 3 strength class.

They are designed for operation in any climatic conditions; in anchor and other ship and floating devices.

Chains for lifting mechanisms

Chains are produced: according to Ukrainian standards and conform to International standards DIN 818-2, 818-3.

Chains of class strength 4 and 8 are made of carbon, alloy and high alloy steel grades depending on class of chain quality.

Application: in chain slings and other lifting mechanisms.

Hardened chains (for fishing industry)

They are produced according to customer requirements from alloy steel by means of heat treatment.

They are applied as ballast for fishing trawl or in other devices with high requirement to surface hardness of chains.

|

Size, mm. [d] |

Pitch, mm.[p] | Inside width, [а] not less , mm | Outside width, [b], not more , mm | Heardness , НВ, not less |

Theoretical weight 1 m. kg |

|

14 |

50 | 17 | 48 | 375 | 4,0 |

|

18 |

64 | 21 | 60 | 375 | 6,7 |

|

19 |

64,5 | 22 | 63 | 375 | 7,6 |

|

19,5 |

64 | 22 | 63 | 375 | 7,6 |

|

22 |

86 | 26 | 73 | 375 |

9,5 |

| 23 | 64 | 27,6 | 83 | 375 |

12,5 |

| 23 | 86 | 26 | 73 | 375 |

10,4 |

| 26 | 73 | 31,2 | 94 | 375 |

15,5 |

| 26 | 92 | 30 | 85 | 375 |

13,7 |

Round link chains for continuous conveyors

3 quality class

Chains are produced according to drawings. They conform to DIN 764.

Size range is between 10 – 33mm. Chains are made of carbon and alloy steels.

They are used for different types of conveyors and traction mechanisms of different branches of industry.

|

Size, [d] х [p]., mm

|

Inside width, [а], min , mm | Outside width, [b] , max , mm | Load, kN | Elongation min, % |

Weight of 1 m , kg |

|

|

proof |

breaking |

|||||

| 10×35 | 14 | 36 | 32 | 50 | 15 | 2,0 |

|

13×45 |

18 | 47 | 53 | 85 | 15 |

3,5 |

| 16×56 | 22 | 58 | 80 | 125 | 15 | 5,2 |

| 18×63 | 24 | 65 | 100 | 160 | 15 | 6,5 |

| 20×70 | 27 | 72 | 125 | 200 | 15 | 8,2 |

| 23×80 | 31 | 83 | 170 | 265 | 15 | 11,0 |

| 26×91 | 35 | 94 | 212 | 340 | 15 | 14,0 |

| 28×98 | 36 | 101 | 250 | 400 | 15 | 16,5 |

| 30×105 | 39 | 108 | 280 | 450 | 15 | 19,0 |

| 33×115 | 43 | 119 | 335 | 530 | 15 | 22,5 |

Round link chains for hoisting machines

5,6,8 quality class. DIN EN 5684

|

Size [d] x [p], мм |

Load, kN |

Weight of 1m, kg |

|||||

|

Proof |

Breaking, not less | ||||||

|

Strength class |

|||||||

|

5 |

6 | 8 | 5 | 6 |

8 |

||

|

13×36 |

67 | 85 | 106 | 125 | 170 | 212 | 3,8 |

|

14×41 |

80 | 100 | 120 | 170 | 200 | 250 |

4,4 |

|

16×45 |

100 | 125 | 160 | 200 | 250 | 320 |

5,7 |

|

18×50 |

125 | 160 | 200 | 250 | 320 | 400 |

7,3 |

| 20×60 | – | – | 250 | – | – | 500 | 8,8 |

| 22×66 | – | – | 320 | – | – | 630 |

10,7 |

Round long link chains

| Size, [d] | Pitch, [p] | Width | Load | Weight of 1 m of chain |

||||

| Inside. [а], not less | Outside, [b] , not more | Working | Test, not less | Breaking | ||||

| mm | kg | kN | kg | |||||

| 4 | 32 | 7,2 | 16,8 | 100 | 2,5 | 6,3 | 0,27 | |

| 5 | 35 | 9,0 | 21,0 | 160 | 4,0 | 10,0 | 0,43 | |

| 6 | 42 | 10,8 | 25 ,2 | 200 | 5,0 | 12,5 | 0,63 | |

| 7 | 49 | 12,6 | 29,4 | 300 | 7,5 | 19,0 | 0,86 | |

| 8 | 52 | 14,4 | 33,6 | 400 | 10,0 | 25,0 | 1,10 | |

| 10 | 65 | 18,0 | 42,0 | 630 | 16,0 | 40,0 | 1,75 | |

| 13 | 82 | 23,4 | 54,6 | 1000 | 25,0 | 63,0 | 2,95 | |

| 16 | 100 | 28,8 | 67,2 | 1600 | 40,0 | 100,0 | 4,45 | |

Special-purpose round link chains produced according to agreed drawings

| Size, mm | Load, kN | Total elongation under breaking load, not les,% | Theoretical weight of 1 m of chains +_5%, kg | ||||

| proof | breaking, not less | ||||||

| Strength class | Strength class | ||||||

| 3 | 6 | 3 | 6 | 3 | 6 | ||

| 13х52х16 | 50 | 140 | 80 | 170 | 14 | 10 | 3,3 |

| 13х60х22 | 50 | 100 | 80 | 170 | 14 | 10 | 3,2 |

| 14х50х17 | 63 | 140 | 100 | 200 | 14 | 10 | 3,9 |

| 14х80х17 | 63 | 150 | 100 | 200 | 14 | 10 | 3,4 |

| 16х55х20 | 80 | 180 | 125 | 550 | 14 | 10 | 4,0 |

| 16х64х29 | 80 | 150 | 125 | 250 | 14 | 10 | 5,0 |

| 16х65х29 | 80 | 200 | 125 | 250 | 14 | 10 | 5,2 |

| 16х80х24 | 80 | 200 | 125 | 250 | 14 | 10 | 4,6 |

| 16х90х26 | 80 | 200 | 125 | 250 | 14 | 10 | 4,6 |

| 18х64х21 | 100 | 250 | 160 | 320 | 14 | 10 | 6,6 |

| 18х80х21 | 100 | 260 | 160 | 320 | 14 | 10 | 6,2 |

| 18х90х26 | 100 | 260 | 160 | 320 | 14 | 10 | 6,2 |

| 19х64,5х21 | 110 | 300 | 180 | 360 | 14 | 10 | 7,4 |

| 19х75х29 | 110 | 260 | 180 | 360 | 14 | 10 | 7,3 |

| 19х100х28 | 110 | 260 | 180 | 360 | 14 | 10 | 6,6 |

| 20х60х26 | 125 | 300 | 200 | 400 | 14 | 10 | 9,0 |

| 20х70х23 | 125 | 300 | 200 | 400 | 14 | 10 | 7,8 |

| 20х80х23 | 125 | 300 | 200 | 400 | 14 | 10 | 8,1 |

| 20х100х28 | 125 | 300 | 200 | 400 | 14 | 10 | 7,3 |

| 22х88х30 | 140 | 320 | 225 | 470 | 14 | 10 | 9,6 |

| 22х110х32 | 140 | 320 | 225 | 470 | 14 | 10 | 9,1 |

| 22х120х32 | 140 | 320 | 225 | 470 | 14 | 10 | 8,7 |

| 22х132х32 | 140 | 320 | 225 | 470 | 14 | 10 | 8,4 |

| 23х64х27 | 160 | 340 | 250 | 500 | 14 | 10 | 12,0 |

| 23х80х28 | 160 | 340 | 250 | 500 | 14 | 10 | 11,3 |

| 24х73х34 | 180 | 460 | 285 | 550 | 14 | 10 | 12,0 |

| 24х86х28 | 180 | 460 | 285 | 550 | 14 | 10 | 12,1 |

| 26х73х30 | 200 | 520 | 320 | 650 | 14 | 10 | 15,1 |

| 26х75х30 | 200 | 520 | 320 | 650 | 14 | 10 | 15,1 |

| 26х92х30 | 200 | 520 | 320 | 650 | 14 | 10 | 13,8 |

| 26х125х37 | 200 | 420 | 320 | 650 | 14 | 10 | 12,9 |

| 28х168х38 | 250 | 450 | 400 | 750 | 14 | 10 | 13,6 |

| 30х90х39 | 280 | 600 | 450 | 870 | 14 | 10 | 20,0 |

| 30х108х34 | 280 | 600 | 450 | 890 | 14 | 10 | 18,0 |

| 32х192х42 | 320 | 700 | 500 | 890 | 14 | 10 | 17,6 |

| 34х126х38 | 350 | 750 | 620 | 1000 | 14 | 10 | 22,7 |

Tested calibrated round link chains

Chains are produced according to drawings and they conform to DIN 766

Range of chain sizes is between 5 and 32mm. They are made of carbon and alloy steels.

Chains are applied for conveying plant of different types and traction mechanism in many fields of industry.

| Size, d x Р , mm | Inside width. а, min, mm | Outsuide width., b , mах, mm | Load, kN | Elongation , min , % | Weight of 1 m, kg | ||||

| proof | working | breaking , min | |||||||

| 5х18,5 | 6,0 | 17,0 | 3,2 | 8 | 12,5 | 15 | 0,5 | ||

| 6х18 ,5 | 7,2 | 20,4 | 4,0 | 10 | 16 | 15 | 0,8 | ||

| 7×22 | 8,4 | 23,5 | 6,3 | 16 | 25 | 15 | 1,1 | ||

| 8×24 | 9,6 | 27,5 | 8,0 | 20 | 32 | 15 | 1,4 | ||

| 9х27 | 10,8 | 30,6 | 10,0 | 25 | 40 | 15 | 1,8 | ||

| 10×28 | 12,0 | 36,0 | 12,5 | 32 | 50 | 15 | 2,3 | ||

| 11×31 | 13,0 | 40,0 | 16,0 | 40 | 63 | 15 | 2,7 | ||

| 13×36 | 15,6 | 47 | 20,0 | 50 | 80 | 15 | 3,9 | ||

| 14×41 | 16,8 | 50 | 25,0 | 63 | 100 | 15 | 4,4 | ||

| 16×45 | 19,0 | 58 | 32,0 | 80 | 125 | 15 | 5,8 | ||

| 18×50 | 21,6 | 65 | 40,0 | 100 | 160 | 15 | 7,4 | ||

| 23×64 | 27,6 | 83 | 63,0 | 160 | 250 | 15 | 12,0 | ||

| 26×73 | 31,2 | 94 | 80,0 | 200 | 320 | 15 | 15,0 | ||

| 28×78 | 33,6 | 101 | 100,0 | 250 | 400 | 15 | 18,0 | ||

| 30×84 | 36 | 108 | 112,0 | 280 | 450 | 15 | 20,0 | ||

| 32×90 | 38,4 | 115 | 125,0 | 320 | 500 | 15 | 23,0 | ||

Trawl chains (for fishing industry)

Round link chains, not calibrated are produced from alloy steel by means of heat treatment.

They are applied as a traction mechanism in lifting trawl devices and in some other devices with high strength chains.

| Size, [d],mm | Pitch, [t],mm | Inside width, [b1] not less than,mm | Proof load, kN | Working load, kN | Breaking load, kN | Theoretical weight of 1m, kg |

| 13 | 52 | 19,5 | 46 | 125 | 200 | 3,34 |

| 16 | 64 | 22 | 57 | 260 | 330 | 5,0 |

| 19 | 76 | 28 | 68 | 360 | 450 | 6,9 |

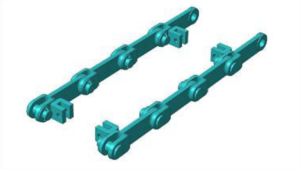

Fork-Shaped chains

These chains are designed to be applied as traction elements of suspended-flight conveyors, feeders and other

lifting and transportation vehicles and devices, including those operating in the reverse mode.

| Position | Name | Designation | Amount |

|---|---|---|---|

| 1 | Link | 10.19-1610 СБ | 2 |

| 2 | Fork | 10.19-1610 | 8 |

| 3 | Shaft | 10.19-1611 | 12 |

| 4 | Screwed washer | 10.19-1612 | 4 |

| 5 | Washer | 10.19-1612-1 | 8 |

| 6 | Splint 6.3×60 GOST 397-79 | – | 12 |

Welded round link chains (cement industry).

Chains made of carbon and high-temperature steels according to special drawings.

They are applied as hinged chains in rotary cement furnace.

There are two types of chains:

|

Type of chain |

Size, mm,d | Pitch,mm,t | Proof load, not less kN. | Working temperature, not higher ,C | Theoretical weight of 1 m, kg |

|

CON |

22 | 120 | 92 | 500 | 9,6 |

|

CON |

25 | 120 | 116 | 500 |

12,3 |

| COG | 22 | 120 | 92 | 800 |

9,5 |

| COG | 25 | 120 | 116 | 800 |

12,3 |