Diverse Approaches to Large-Scale Casting

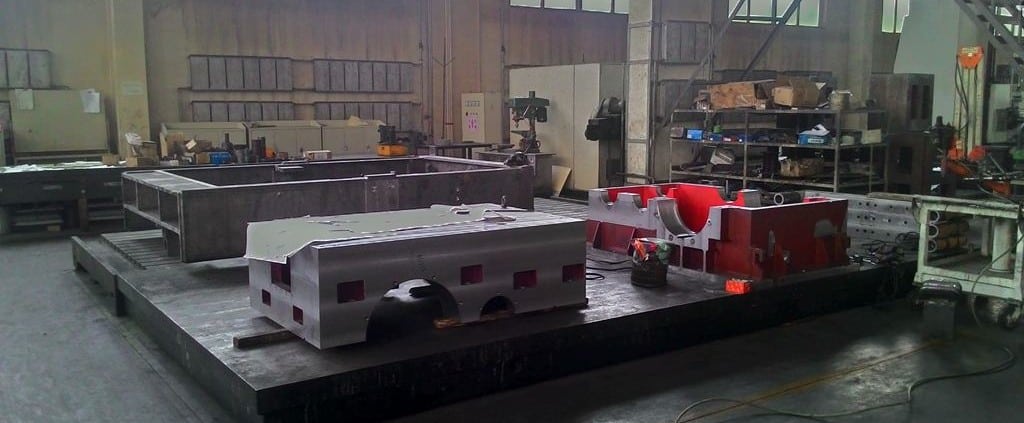

Our journey in large-scale stainless steel casting unfolds through a symphony of precision and innovation. Depending on the exacting requirements of product quality, we employ either machine or manual molding techniques, tailoring our approach to each project’s unique demands.