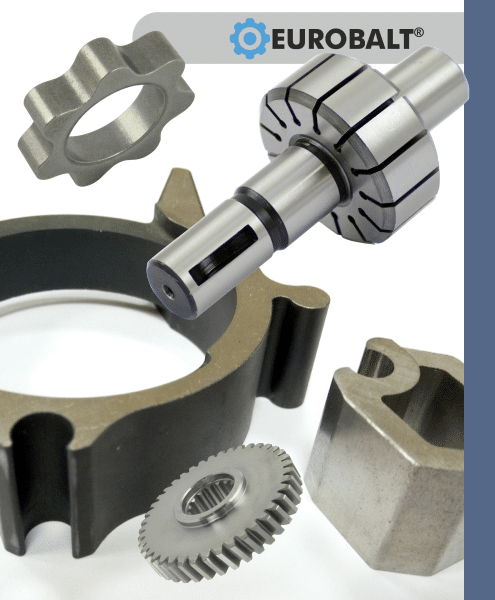

POWDER METALLURGY MANUFACTURING

We manufacture and supply powder metallurgy products using following technologies

Powder Metallurgy by Eurobalt

European powder metallurgy manufacturer and supplier for different industries and equipment components.

As a European supplier of powder metallurgy products, we offer customized solutions and a complex approach. From tooling and first samples to series production. We provide full engineering support for our customers.

We manufacture and supply powder metallurgy products using following technologies

Powder metallurgy is an innovator in modern technology and offers a number of benefits. The process allows products to be manufactured with high precision, offering unique performance and durability.

Its adaptability in manufacturing, ability to create complex designs and resistance to extreme temperatures make it indispensable in the aerospace, medical and automotive industries.

In addition, resource efficiency and waste reduction contribute to sustainable, green manufacturing.

To produce items with hight precision in shape and size, guaranteeing strength and resistance to wear and tear.

Empowering the creation of complex geometric forms, surpassing the limitations of traditional manufacturing methods.

Minimizing waste through efficient material usage and recycling, aligning with sustainable practices for environmental conservation.

Utilizing an extensive range of metallic powders, facilitating the creation of products with diverse and tailored properties.

Streamlining production through rapid manufacturing processes and the integration of multiple stages, ensuring economic viability without compromising quality.

We create the perfect blend of metal powders to form the perfect component that will meet all your required parameters and characteristics

Once samples are accepted, and the order is placed, we start working as one. Preparation of production and raw materials, our team works for your result.

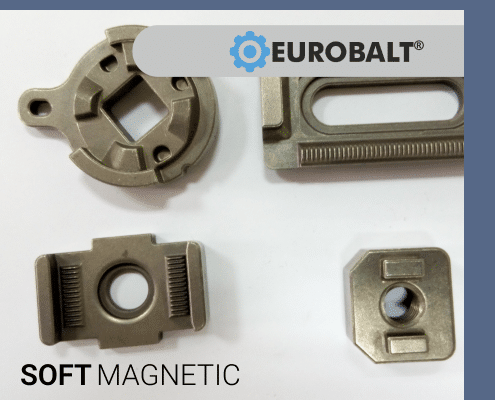

Special soft magnetic parts are made using powder metallurgy. They are used to amplify or direct the magnetic field. With such products an electrical signal can be converted into motion or vice versa. Such parts are easily magnetized or demagnetized when the magnetic field appears or disappears.

Such parts have many advantages. They have less weight, better magnetic characteristics and reduced noise vibrations. Therefore, powder metallurgy is widely used in the production of various components of electric cars.

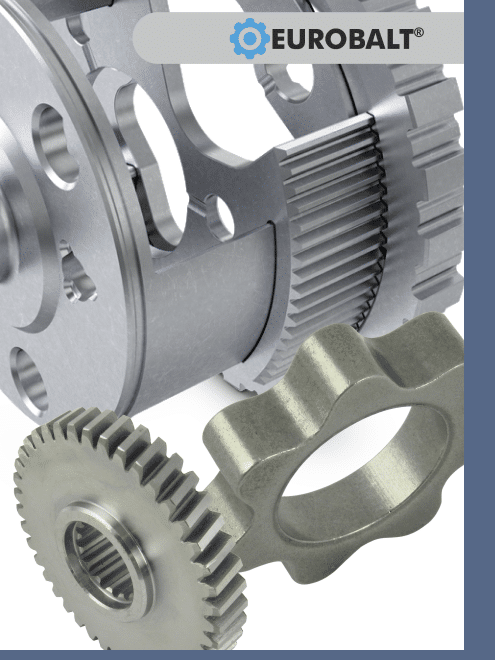

Powder metallurgy in the automotive industry is used to produce unique metal components that are not possible or difficult to produce using traditional metal processing methods. The use of powder metallurgy is very widespread in the automotive industry. This is because this method of manufacturing parts is quite universal, flexible and economical.

By using this method of production, manufacturers are able to control product porosity, consistent product dimensions and control the tightest dimensional tolerances in the market.

Eurobalt®

Valge 13, 11415

Tallinn, Estonia

office@eurobalt.net

+372 650 60 96

sales DPT: +372 5693 1399

Skype: eurobalt.engineering