Designing a hydraulic cylinder

can be a complex process that requires a deep understanding of the application’s requirements and the cylinder’s functionality.

To ensure optimal performance, it is essential to take into account the cylinder’s bore, rod diameter, stroke length, and operating pressure. Begin by gathering the necessary information, including the maximum force the cylinder needs to produce, the speed of operation, and the environment in which it will operate. Once you have this information, you can start designing the cylinder using software such as SolidWorks or AutoCAD.

Next, choose the appropriate materials for the cylinder’s components, such as the piston, rod, and seals. Consider the operating temperature, pressure, and any external factors that could impact the cylinder’s durability. After selecting the materials, it’s time to determine the cylinder’s dimensions. Calculate the bore and rod diameter based on the required force and the operating pressure. The stroke length is then determined by the distance the cylinder needs to move. Once you have a preliminary design, simulate the cylinder’s performance using software or physical testing. Make any necessary modifications to ensure optimal performance and durability.

Finally, choose a reputable manufacturer to produce the cylinder according to your design specifications. A well-designed hydraulic cylinder can improve system performance, reduce downtime, and ultimately, lead to increased efficiency and profits.

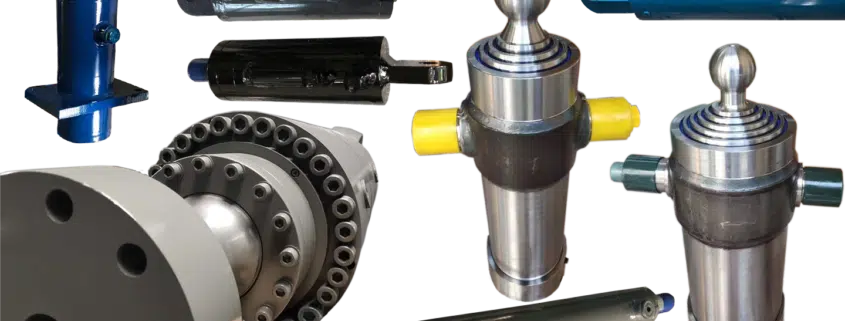

Explore the creative process and bring your vision to life by designing a custom hydraulic cylinder that perfectly matches your unique specifications and requirements.