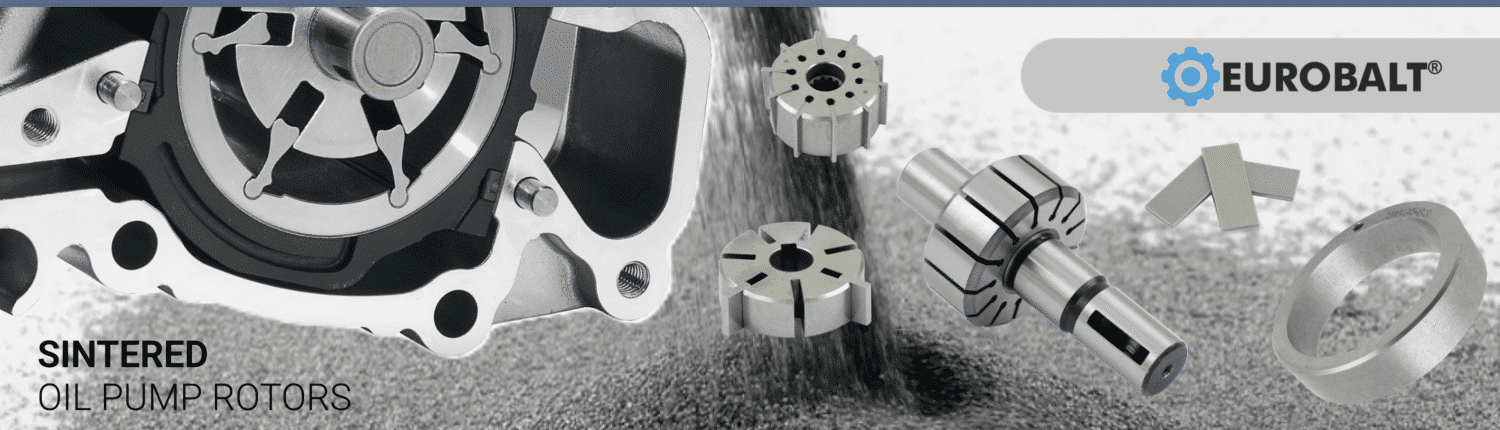

Oil Pump Rotors – Precision Engine Components

Oil pump rotors, integral to the heart of internal combustion engines, exemplify precision engineering and reliability. These vital components facilitate the circulation of oil, ensuring optimal lubrication and engine performance.

Production of oil pump rotors by powder metallurgy process

Oil pump rotors are manufactured by the powder metallurgy process, which begins with the transformation of metal powders into precision parts.

Metal powder selection and sealing:

The process begins with the careful selection of metal powders, often high-quality alloy steels or specialty materials selected for their desired properties. These powders are carefully blended to achieve the optimum composition. The powder mixture is then subjected to tremendous pressure in precisely designed dies through controlled compaction. This compaction results in the formation of oil pump rotor blanks with the desired geometry.

Sintering process:

The green rotor blanks then undergo a critical stage known as sintering. In this stage, the compacted powders are heated at elevated temperatures, below the melting point, in a controlled atmosphere. This heat treatment causes solid state diffusion of atoms, which bonds the particles together, eliminates porosity and solidifies the rotor material. The sintering process gives the rotor blanks increased density, structural integrity and mechanical strength.

Forming and finishing:

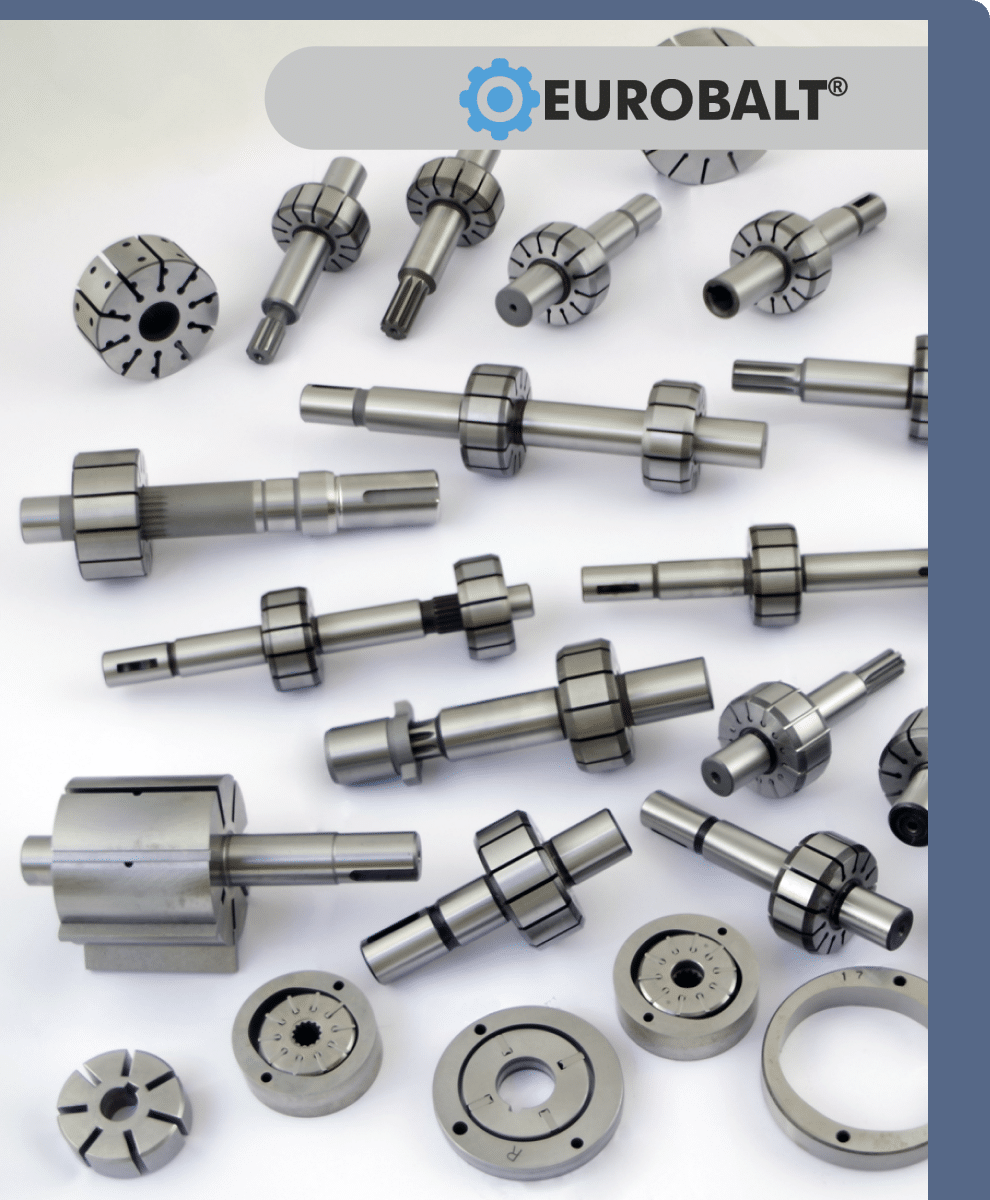

After sintering, oil pump rotors undergo forming and finishing processes. Precision machining techniques, such as CNC and other machining, allow the rotor to be given a final profile, ensuring precise geometry and surface finish.

Refinement and Additional Processing

Surface Enhancement for Optimal Performance

Once the oil pump rotor undergoes the primary powdered metallurgy process, additional treatments are often applied to enhance its surface properties. These treatments aim to improve wear resistance, hardness, and overall performance under challenging operating conditions.

Nitriding

Nitriding is a surface-hardening process that involves diffusing nitrogen into the surface of the rotor material at high temperatures. This treatment forms a hardened layer on the surface, increasing its resistance to wear, corrosion, and fatigue.

Coating Technologies

Advanced coating techniques, such as DLC (Diamond-Like Carbon), are employed to further enhance the rotor’s surface properties. DLC coatings provide exceptional hardness, low friction, and excellent wear resistance, contributing to prolonged component life and improved efficiency within the engine.

Balancing and Quality Assurance

Precision Balancing

Ensuring the oil pump rotor’s precise balance is a pivotal step in guaranteeing minimal vibrations during operation, an imperative element for the seamless functionality of the oil pump. Employing cutting-edge balancing techniques, each rotor is carefully tuned to achieve optimum balance, significantly reducing operational noise and mitigating wear on crucial engine components. This meticulous approach not only enhances the pump’s efficiency but also extends the overall lifespan of the engine.

Strict Quality Control

Our company is based on a commitment to quality. We employ stringent quality control measures throughout the manufacturing process. From detailed metallurgical analysis to comprehensive dimensional checks and thorough hardness testing, our rigorous evaluations ensure that each rotor meets, and sometimes exceeds, the most stringent industry standards and precisely meets our customers’ specifications. These comprehensive checks ensure that every oil pump rotor leaving our facility embodies the precision, durability and reliability required for optimum engine performance.

See for yourself. Simply fill out the form to the right and send us your drawing.

Industrial production according to your requirements

Every engine deserves the pinnacle of performance (also find out about our sintered gears and other parts). Our commitment to precision and quality sets us apart. Manufactured to your exact specifications, our components ensure optimal performance and smooth operation.

Contact us today for a custom quote. We guarantee a constructive dialogue!