Eurobalt Grupp provides its customers with the best sintered parts production service.

With the lowest costs and the highest product quality

Sintered parts manufacturing is an environmentally friendly, economical and efficient technology for the mass production of metal products. Thanks to zero-waste production and an optimized process flow, production costs are significantly lower than traditional metalworking methods. We can produce very large batches of sintered parts in a short time, with the lowest CO2 footprint, with less energy usage and without waste.

Eurobalt Grupp provides its customers with the best sintered parts production service.

With the lowest costs and the highest product quality

All our sintered parts conform to industry and generally accepted international standards.

If required to produce sintered parts with unique properties, our engineers develop customized powder blends. This ensures we meet all necessary parameters as per customer requirements.

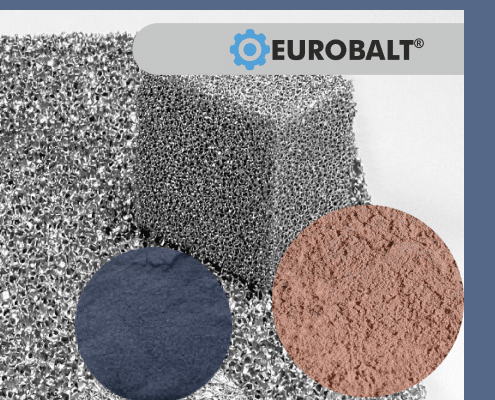

A carefully selected metal powder blend is utilized for every sintered component to ensure the product meets requirements for density, hardness, tolerances, dimensions, strength, and wear resistance.

Our engineers’ responsible and meticulous approach to producing each customer’s components results in superior performance compared to our competitors’ sintered parts.

At Eurobalt, we pride ourselves on offering a diverse selection of standard metal powders for sintered part production. Our wide range of materials allows us to cater to a multitude of customer requirements and specifications. Whether you’re looking for strength, corrosion resistance, or unique properties, our selection has you covered:

Choose Eurobalt for your sintered part needs and harness the potential of our diverse metal powder offerings.

Our materials are ready to bring your innovative ideas to life, meeting the highest standards of quality and performance.

Contact us today to discuss your project requirements and explore the possibilities with Eurobalt.

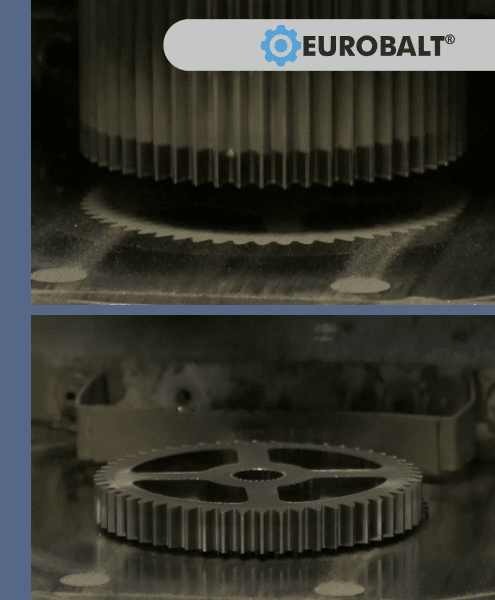

At Eurobalt, we use a time-tested solution to create sintered parts. This traditional technology delivers superior results, achieving high densities in seconds during the pressing phase. This efficiency allows for faster production and the ability to produce large batches within tight schedules.

However, it is important to note that different metal powders react differently to the pressing process, and the press density achieved can vary for each new green part. To ensure optimal uniformity, we use high-quality tooling and add special lubricants to the metal powder mixture.

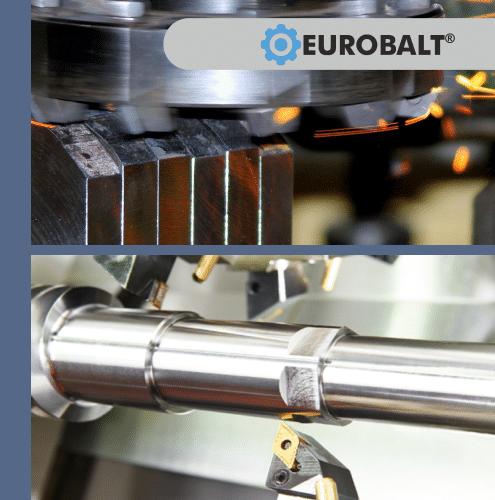

One of the most important advantages of our sintered metal parts is their precision. They conform to all required dimensions and tolerances, eliminating the need for additional machining. Our team consists of skilled engineers who design the production tooling, which we manufacture in-house.

This approach allows us to fine-tune and optimize the entire production process. Equipped with state-of-the-art CNC machines and presses, Eurobalt is able to quickly produce high quality sintered metal parts, even in large volumes. We consistently strive to deliver sintered parts that are not only reliable, but also of exceptional quality. From start to finish, Eurobalt monitors the entire production process to ensure that each sintered component meets your expectations. Trust us for accuracy, reliability and on-time delivery.

Ready to Transform Your Vision into Reality?

Contact us today to initiate the process. Our skilled team and cutting-edge technology are poised to bring your sintered part ideas to life. Let’s craft excellence together.

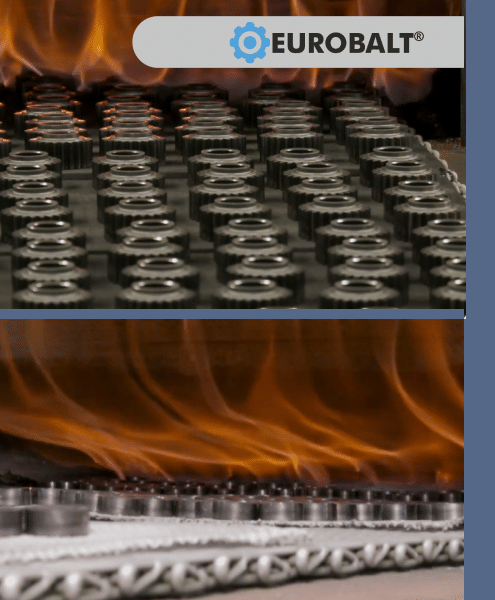

After forming, the parts get sintered.

Our high-temperature furnaces ensure constant temperature control during the sintering process.

We invest in equipment, energy-saving initiatives, and solutions to boost productivity and cut production costs. All parts are placed in a specialized furnace where the sintering atmosphere is carefully controlled, and the temperature can reach 1429℃.

During the sintering stage, the parts are heated to a temperature below the metal’s melting point, from which they are molded, and held at the set sintering temperature. During the sintering stage, the parts are heated to a temperature below the metal’s melting point, from which they are molded, and held at the set sintering temperature. The sintered parts are subsequently cooled.

Strong bonds are formed between the metal molecules during the sintering process.The sintering process delivers the complete properties of the final sintered component as a fully-formed metal product.If required, the sintered part is immediately available for further processing or other types of finishing operations.

Eurobalt enforces rigorous quality control throughout all production stages, ensuring our company is a reliable partner.

Generally, sintered parts require no additional machining and are ready to use. Eurobalt can perform additional finishing of the sintered part if required. This is usually required for more complex parts or when higher dimensional accuracy is needed. We can perform additional operations to increase the strength of the sintered part, to improve the corrosion resistance, to improve the performance of any part we produce.

Eurobalt can provide a full range of additional processing of sintered parts, which includes:

These and many other methods of secondary processing of sintered parts, allow us to provide a complete production cycle, which is an important advantage in the market.

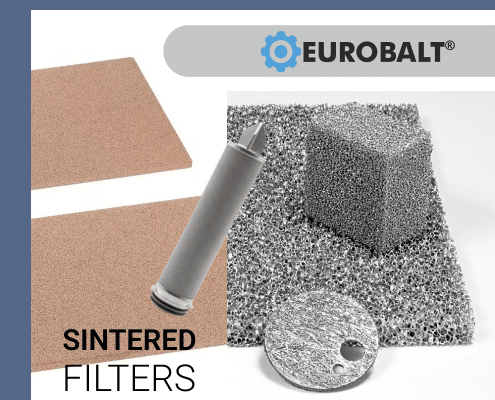

Filtration solutions for various industries

Our production provides sintered filters with a high degree of filtration, with a good degree of mechanical strength and an excellent throughput capacity.

Let’s do it together! Send us your drawings or email us and we’ll get back to you.

Eurobalt®

Valge 13, 11415

Tallinn, Estonia

office@eurobalt.net

+372 650 60 96

sales DPT: +372 5693 1399

Skype: eurobalt.engineering