Metalwork services

Our different manufacturing technologies for the production of metal parts.

Our sintered metal parts production capabilities.

Our die casting manufacturing capabilities.

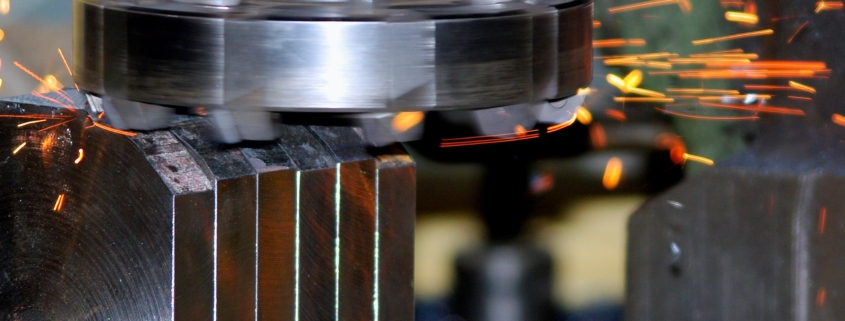

Our technical possibilities for machining and CNC.

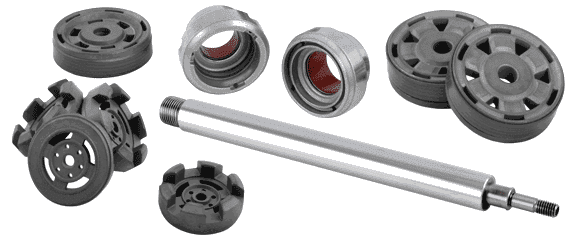

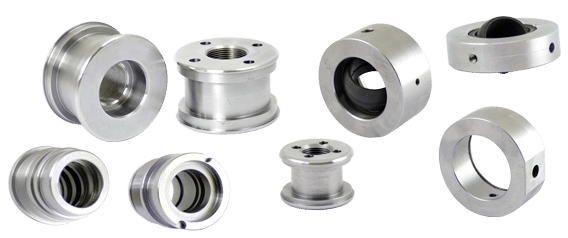

Production of shock absorber parts of any complexity, according to client’s drawings.

Рydraulic cylinder piston, hydraulic cylinder bushings, cap end of the cylinder, cylinder rod, and other components.

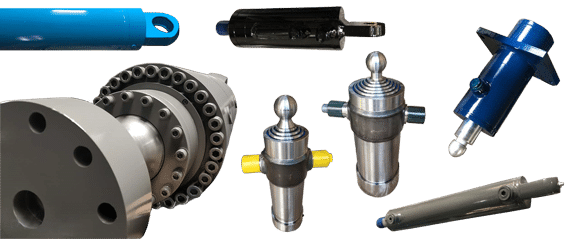

We produce Hydraulic cylinders of any complexity and size.

Our technical possibilities for manufacturing permanent magnets.

Our large-scale steel and stainless-steel casting capabilities.

Our technical possibilities for sintered filters manufacturing.

Supplier of metal parts manufacturing

Other than our main manufacturing technologies (powder metallurgy, die casting and machining), our company offers additional value-added services in the manufacturing of metal parts. Even though these additional services are not our principal activities, we count with the technical and production capabilities to manufacture parts with special additional requirements.

When carrying out orders for metal parts at our production facilities, we often receive requests from our customers to manufacture parts through other manufacturing technologies We understand that quality as well as meeting production and supply deadlines are very important for our customers, and we are aware that trust plays a key role too. Through our team of professionals and engineers, excellent own quality control system and many connections with other manufacturers, we are able to meet different special manufacturing requirements.

We assist our customers in the manufacturing of parts that require special technologies, by outsourcing (subcontracting) the manufacturing to one of our highly trusted manufacturing partners. When subcontracting, we control the whole manufacturing process; our engineers study the drawings carefully and design a necessary tooling, we control the production of first samples as well as batch production and then our company inspects and accepts finished products and supplies them to our customers. This is another additional advantage for our regular clients and future partners, as we assist our customers in all aspects concerning production and supply of required products, using our technologies or technologies available from our partners.