We manufacture tungsten carbide products through the process of powder metallurgy, by pressing, in order to get a required shape and then sinter the parts in furnaces at 1350-1450 ºC.

The main distinctive feature of tungsten carbide products is their hardness, which is close to the hardness of diamond.

Due to their unique combination of properties, products made of tungsten carbide are used by manufacturers in a wide range of industries.

A large number of the products are used in both output goods and production tooling.

Eurobalt manufactures a wide range of finished and semi-finished products made of tungsten carbide for its customers. We are always open to new business relationships and ready to give the best offer for tungsten carbide products.

Technological capacities

Minimum possible weight of the part: 0,001 kg Maximum possible weight of the part: 300 kg Minimum possible sizes of the part: Ø3mm, others not limited Maximum possible sizes of the part: 500mm Minimum possible wall thickness: 0,1mm Maximum possible wall thickness: No limitations Tolerances achieved by pressing and sintering: +/- 0,15mm Tolerances achieved after machining: +/- 0,01mm Minimum possible batch: 500 kg

Standard materials used in manufacturing

YG 6 YG 11 YG 20 YN 9 YG 8 YG 12 YG 22 YN 10 YG 9 YG 10 YG 25 YN 11 YG 10 YG 20 YN 6 YN 13 YN 15

Equipment used for manufacturing

Pressing equipment: 12 units Sintering furnaces: 10 units Equipment manufacturer: Bairuilong Pressing machines year of production: 2001-2013 Sintering machines year of production: 2001-2013

Parts and their application

- Wear and tear products

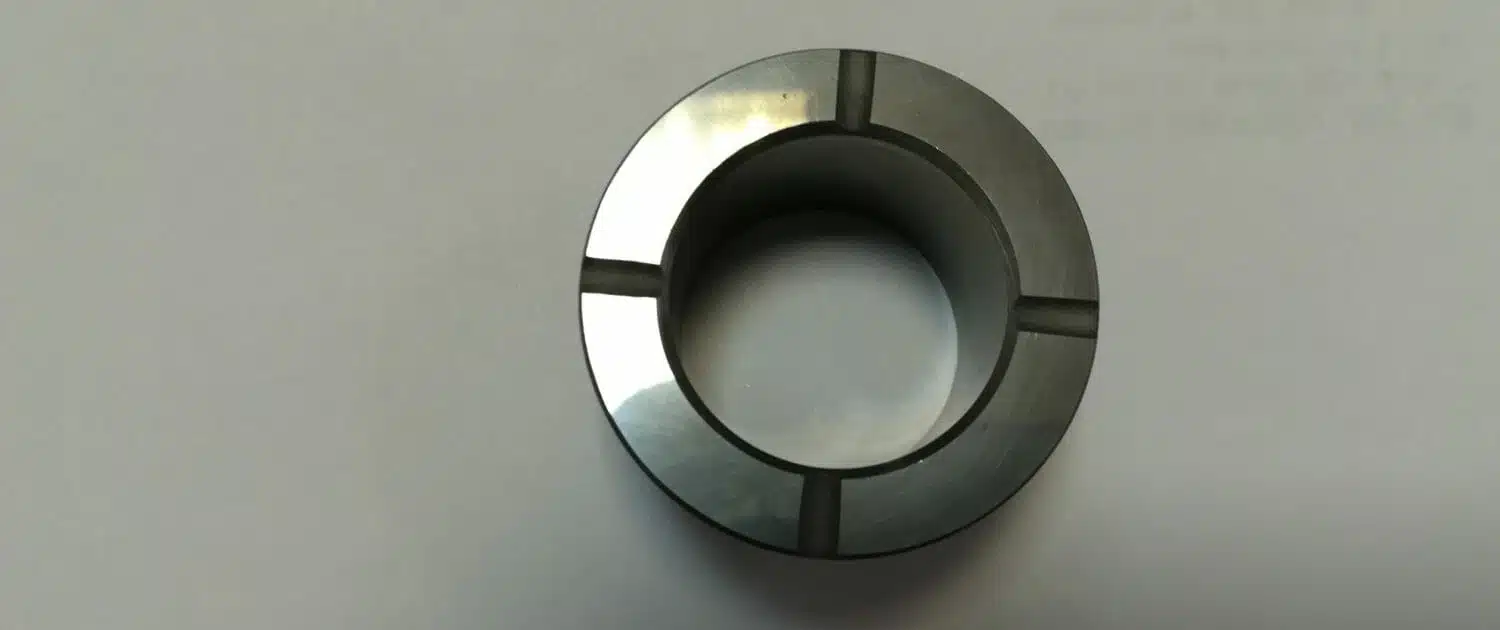

- Valve parts, Valve cores, Seal rings

- Bushings, Plungers and sleeves

- Carbides for oil and gas industry

- Carbides for DTH and PDC drill bits

- Carbides for geological exploration

- Tungsten welding parts