Neodymium magnets are the strongest, the most important and frequently used permanent magnets nowadays, they have wide application in different industries.

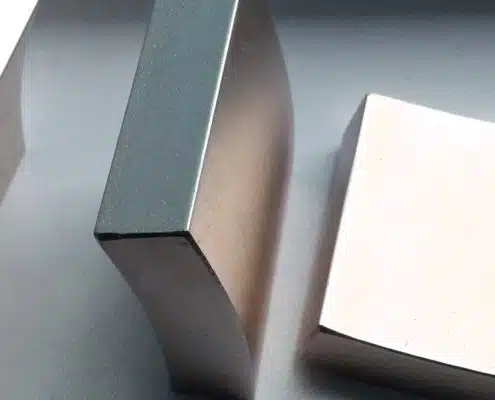

Eurobalt manufactures and supplies permanent magnets with different magnet characteristics, physical properties, and shapes.

We pay special attention to transport packaging of magnets because of their fragility.

We also pay particular attention to magnetic isolation which is needed during transportation since a strong magnetic field of permanent magnets significantly affects electric vehicle equipment.

Technological capacities

Maximum weight of the magnet: 2,5 kg Minimum possible sizes of the magnet: Depends on magnet requirements Maximum possible sizes of the magnet: Length 100mm, or Ø200mm Best possible tolerances: +/- 0,2 mm

Manufactured magnet classes

N35 N35M N33H N33SH N38 N38M N35H N35SH N40 N40M N38H N38SH N42 N42M N40H N40SH N45 N45M N42H N42SH N48 N48M N45H N45SH N50 N50M N48H N33UH N52 N35UH N38UH

Standard materials used in magnets coating

- NiCuNi coating - Epoxy - Zing - Parylene

Other possible coating materials

Nickel (Ni) Silver (Ag) Gold (Au) Tin (Sn) Chrome Ni-Cu-Ni + Parylene С Ni-Cu-Ni + rubber Ni-Cu-Ni + Epoxy Zinc Chromate Zing + rubber

Parts and their application

- Robotic equipment and automated industry

- Electric equipment

- Lifts

- Magnets for various equipment

The materials that are used in the production of permanent magnets possess different magnetic properties, they require different production processes and have their advantages and disadvantages.

We manufacture permanent magnets of various sizes and shapes imparting a range of magnetic properties to them as well as coat the magnets with different materials, depending on the requirements of our customers.