Eurobalt Engineering is a powder metallurgy company. We accept production inquiries for sintered and pressed parts. Thanks to its modern technological equipment, our company can manufacture large batches of high-quality products quickly. We make sure that the manufacturing process is being monitored closely, which guarantees high quality of products and their compliance with the requirements of project documents.

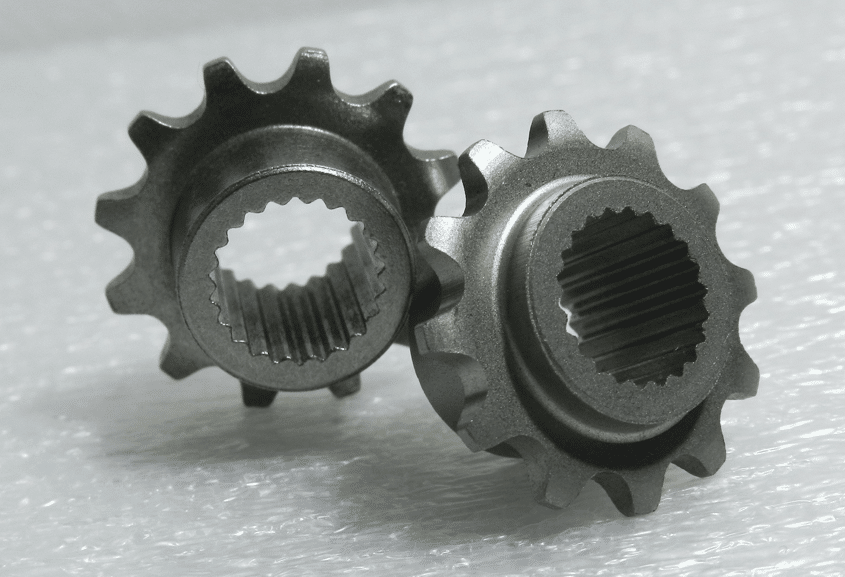

Pressing and sintering technologies of powder metallurgy manufacturing have been applied in industry for a long time. Powder metallurgy allows to produce parts with complex shapes or with a big amount of holes with a minimal material loss. This technology is used for manufacturing flanges, gears, and other components that fall into the category of sintered products.

The manufacturing process consists of several stages:

- Preparing a powder mixture, which can only be made of metals or with the addition of other components. In order to produce powder, metal is mechanically ground and dispersed after being melt or undergoing chemical reactions.

- Forming a billet by cold pressing.

- Sintering the mixture to make a solid product.

Finished sintered parts are calibrated to reach perfect geometric shapes and precise dimensions. The parts can also undergo additional machining and be treated with a lubricant if needed.

The parts, manufactured by pressing and sintering metal powders, have many advantages, such as high strength, strain stability, and thermal stability. Adding other components to a powder mixture will help increase strength, friction coefficient, and other parameters of a finished part. Such features allow to use the parts in different industries.