The parts are used in different industries:

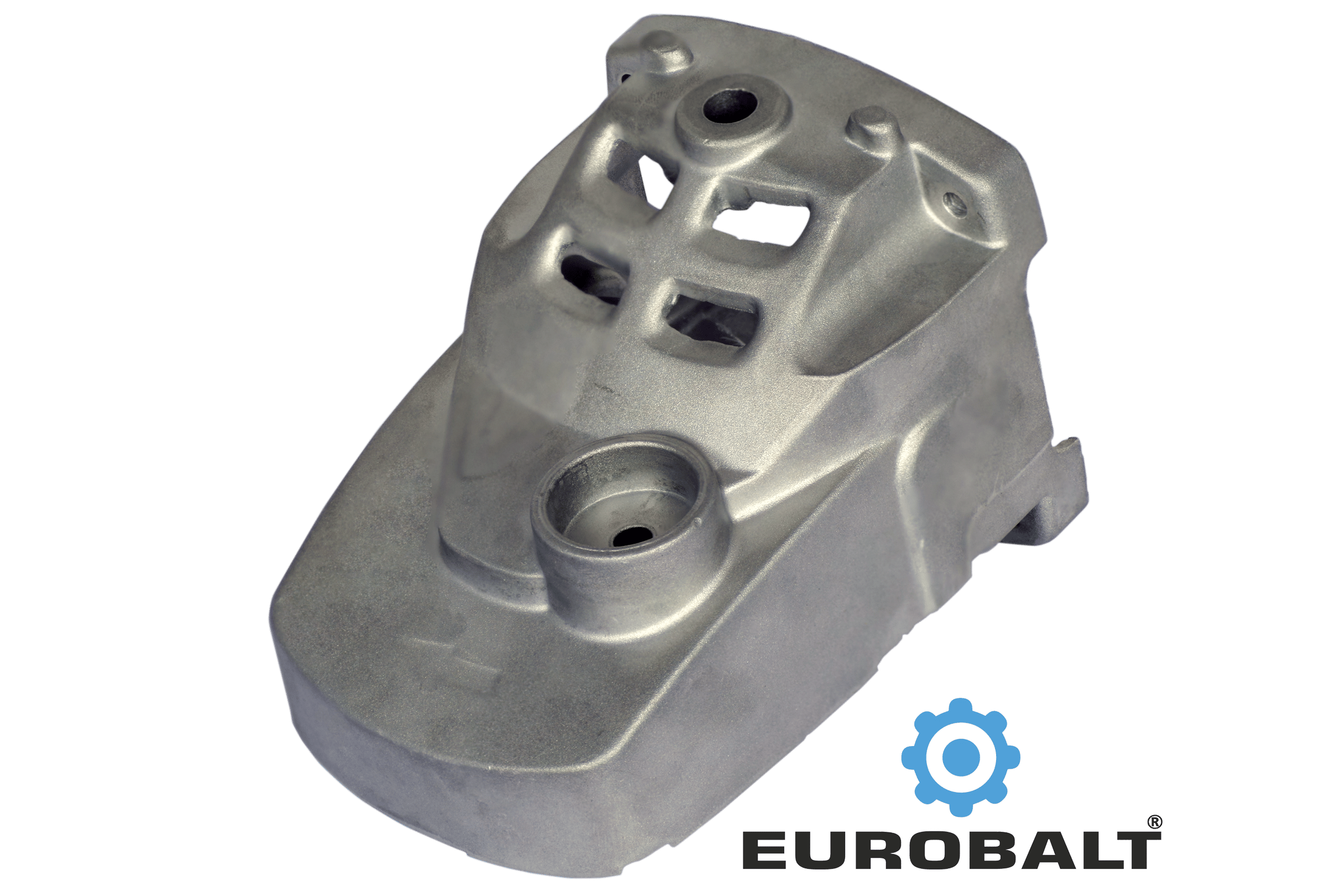

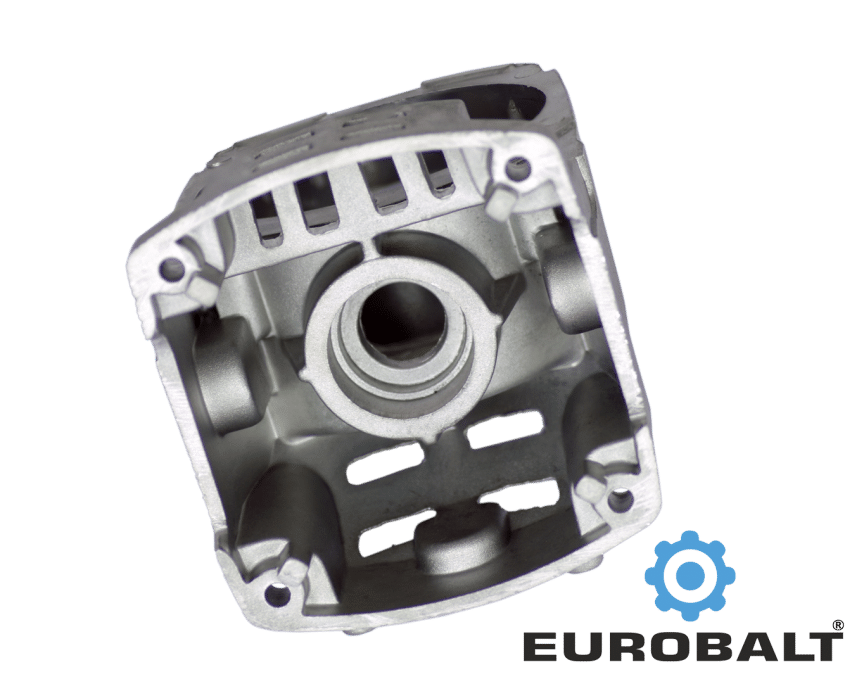

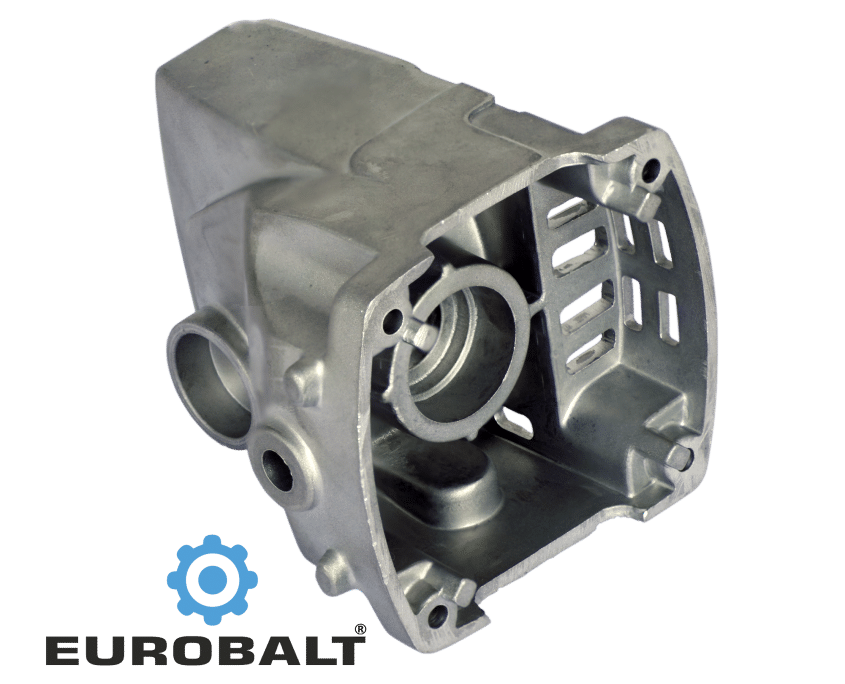

Our company has modern production lines to manufacture die casting parts of any shapes and sizes.

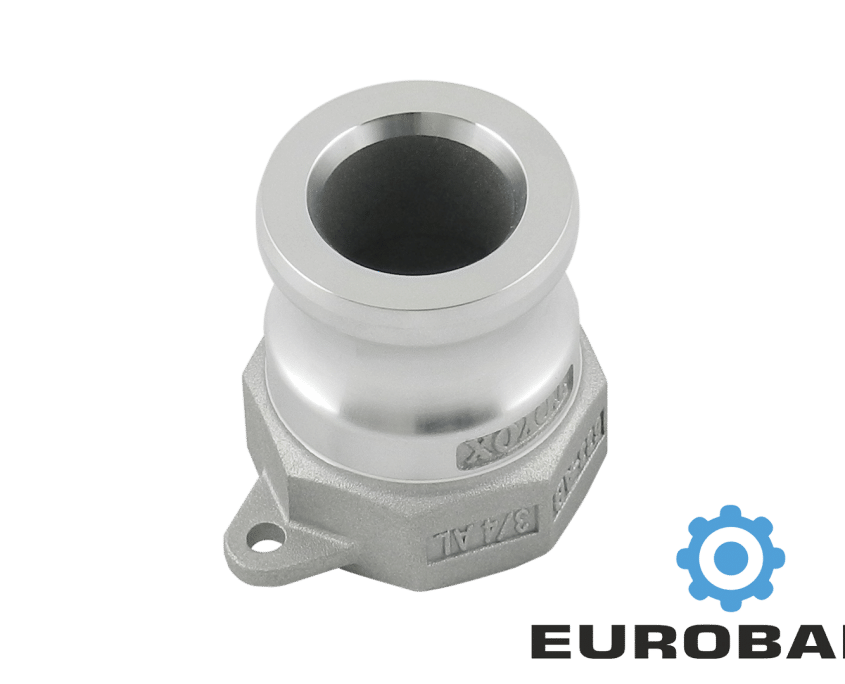

With the help of die casting technology it is possible to produce complex moulded parts with a minimal wall thickness and precise dimensions. The parts can be produced with a smooth surface or thread, they can have working holes, inscriptions, etc.

The advantage of this technology is that in many cases metal billets do not require additional machining as their surfaces and linear dimensions correspond to the parameters of finished parts. It speeds up the manufacturing process and reduces material waste.

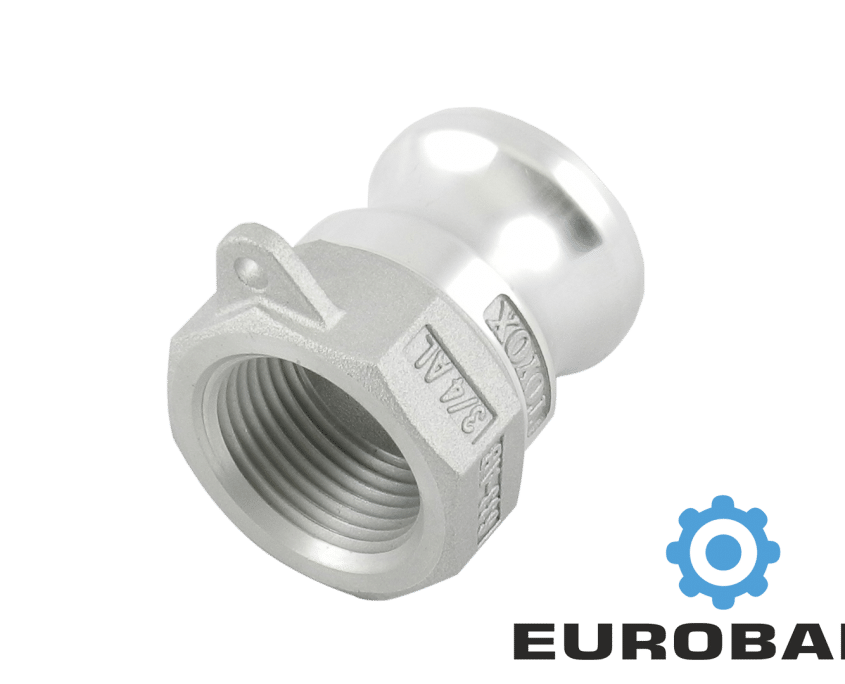

Our company uses aluminium, magnesium, and zinc-based alloys to manufacture die casting parts. They have light weight and low melting temperatures. We would like our customers to consider using a zinc alloy for manufacturing die casting parts. This kind of raw material is used less often than aluminium, but it has a number of advantages.

Zinc alloy die casting parts are produced by machines with hot press chambers. Zinc has a lower melting temperature than aluminium and magnesium. Due to its high fluidity, zinc is an optimal choice for manufacturing complex-shaped parts with thin walls. Another advantage of zinc alloy die casting parts is that there is no need for surface machining to smooth the relief, which reduces the total manufacturing cost.