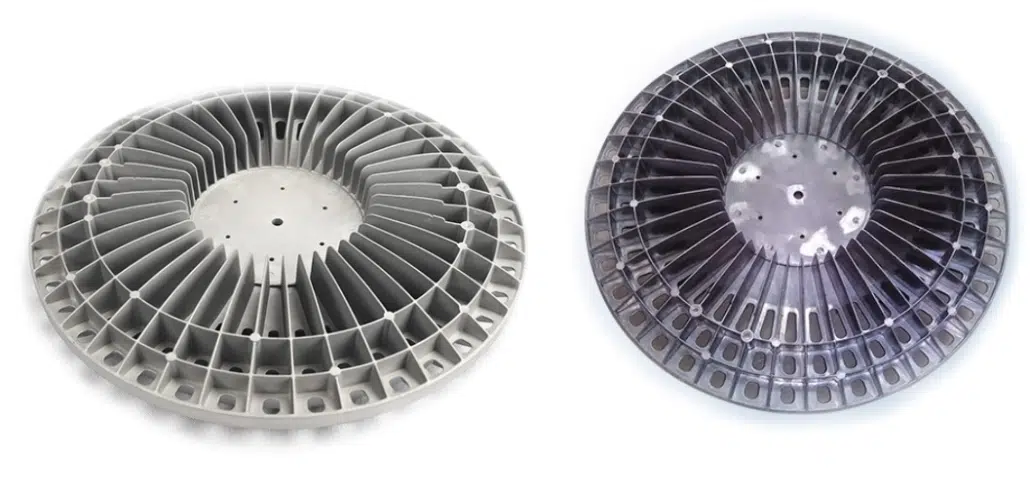

Aluminium die casting in LED light manufacturing

The aluminium die casting process is applied to manufacture various parts. Aluminium is widely used in the production of different housings, radiators, LED lights, in aircraft construction, radio engineering, etc.

What do aluminium radiators do?

With the emergence of new technologies, it has become possible to create lighting devices based on LED matrices and strips. However, they heat a lot when working and can fail to work after reaching a certain temperature. In order to prevent it from happening, radiators with LED matrices are used. The cooling element is a special aluminium profile.

Such radiators actively take away a large amount of heat from the surface of a lighting element, which is necessary when installing high capacity matrices. Profiles often have grooves for attaching glass or transparent plastic covers that will protect the LEDs from adverse environmental factors, such as bad weather when installing lamps on the street.

There are certain advantages of using a profile. For example, you can easily cut off an unnecessary piece if it does not fit the size of the housing or the LED matrix.

Standard profiles are:

- triangular, round, rectangular;

- complex;

- with rounded edges.

Where are they applied?

Recently, there has been a great demand for street lamps with LED matrices (LED technology), since they have several advantages. First, the economic benefit is obvious as they consume a small amount of energy. Secondly, they have a longer service life compared to any other lamps.

Lighting fixtures are often installed into injection moulded housings. The cooling element is made of anodized aluminium and coated with a special compound that protects from tarnishing and corrosion. In this way, the lighting is done in parks, squares, airports, and in places where a warm, flat, bright light is required.

The simplicity and versatility of the aluminium parts (profiles and housings) manufactured using die casting allow to fix them not only on the posts but also on the walls of various objects, in the floor, on the runways of airports, etc. Some of them can be fastened at once by several strips with RGB diodes or matrices. This quality is widely used by designers to create various light compositions, the lighting of cultural objects (for example, museum entrance, monuments) and other buildings.