Is machining necessary for sintered parts produced by pressing?

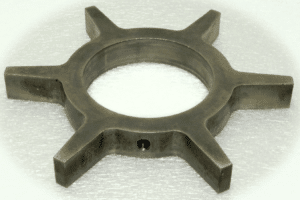

The pressing technique of powder metallurgy is one of the most progressive methods in the production of high-precision parts from various metals, alloys, and pseudo alloys. The method of pressing is used for manufacturing both large-sized products and separate parts of complex mechanisms, for example, oil pumps rotors.

Pressing and machining of metal parts

Pressing and sintering of powder mixtures make it possible to set the required parameters to the part placed in the mould at the very beginning, which is necessary in order to achieve precise dimensions of a finished metal part. Machining may be required for certain types of products. This technological process allows producing parts with the parameters specified in customer drawings. Such parts can have holes in them. Non-pressed parts of a product are removed mechanically, after which working holes appear.

The mechanical method of post-processing of parts helps to remove sharp notches, to grind sharp edges, and to clean lugs. Surface grinding and polishing may be also required.

Losses of material during machining of products manufactured by pressing are minimal and rarely reach 3-4%. This helps to reduce the cost price of produced parts, which ultimately has a positive effect on the price for the final customer.

The final stage of product processing is carried out using different machine tools, such as grinding and drilling machines, barrelling machines, and threading machines. In mass production, automatic production lines, each of which is programmed to perform one operation, are used for machining.

One of the main specializations of our company is the production of a wide range of components and parts using the following manufacturing processes: powder metallurgy, aluminium die casting, machining, and forging. The highest precision of finished parts, which can be also achieved by post-processing, allows our customers to use them for the assembly of necessary components and parts in the future.