Sintered Gear Applications

Sintering is a manufacturing process that uses extreme pressure to turn a mixture of powdered metals, alloys, and binding agents into a solid shape. While the process was introduced in the 1940s, many industries have since leveraged its benefits.

Sintering is commonly used in applications such as automotive and power tool gears.Although sintering is versatile and can produce many shapes, we will focus specifically on the crucially important gear components.

Gears, whether with internal or external teeth cutouts, are not only simple to look at but also diminutive in size.Despite their small form factor, they are an indispensable component of any mechanically or electrically functioning device.The history of gears dates back to the era when metals weren’t even used. Instead, big wooden structures with teeth cut into them were employed for heavy lifting tasks. As time passed, metallurgy brought alloy gears made with metals like steel and brass. Today, one can find gears in small devices like a wristwatch to big machines like a motor engine. Sintered gear applications are widespread in different industries. However, here are a few sectors that utilize them the most.

There are other industries such as marine where gears and their use is seen but these five have exponentially high usage rate.

Advantages of Sintered Gear

As it is evident, if a motor is involved, a gear is not far behind in helping transfer of that power through different designs, shapes and sizes of equipment. While there are cases where other types of gears are used, but in most cases, sintered gears are preferred and there are several reasons for that.

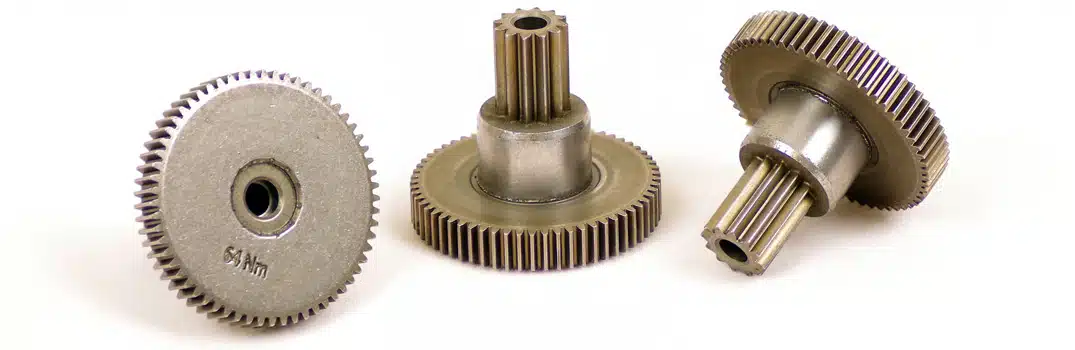

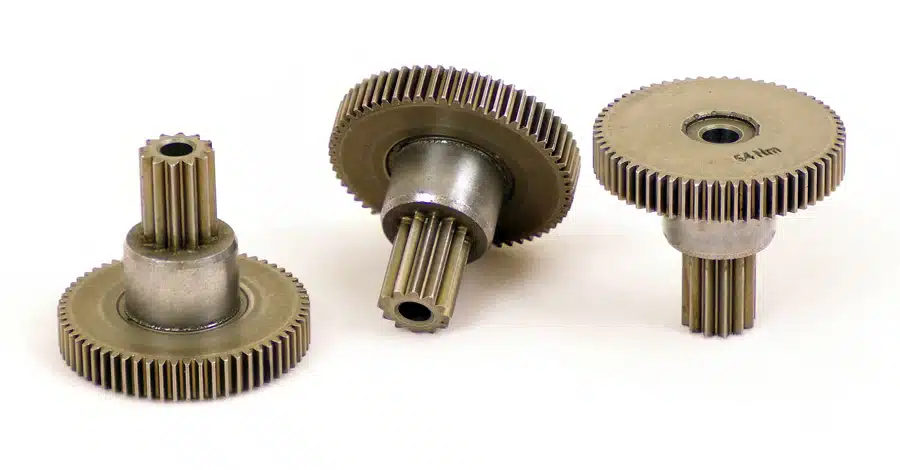

At Eurobalt, we manufacture sintered gears for various applications, whether you require helical, bevel, pinion, combination, or spiral bevel shapes.Our powder metallurgy solutions are tailored to meet each customer’s specific needs. Take advantage of our years of expertise in the sintered gear production process to see how it could enhance your manufacturing requirements. Call or email us and one of our sales experts will assist you in making the best decision for your project.