The use of aluminium die-casting

Aluminum Die Casting housings have various qualities that’s made it indispensable in manufacturing process. Ever since the material was put into a mold to give it shape, the product has stayed with us since then. While die casting from various other materials is possible, aluminum is the most used of them all and housing is the biggest form factor build with the material and process. Here we try to explain some Aluminum die casting housing applications and why it is used in the first place.

Die casting is a process of pouring hot liquid material into a set mold so that the material, when it cools, will take the shape of the desired mold. That is not a new manufacturing concept, some 200 years ago the idea took shape and it has been refined to the point where we use it now. Since die casting has made it giving shapes to metals easy, one the biggest beneficiary has been the housing form-factor. So, here are some of the industries where Aluminum Die Casting housing applications are prevalent.

From bulbs in a room to the smartphones and smartwatches in our person at all times, they all use Aluminum Die Casting housings.

- Electrical Conductivity Industry: When it comes to conductivity of electricity silver, copper and gold are the three most conductive elements. They are also expensive considering the fourth most conductive element in aluminum. That is why electrical equipment utilizes aluminum die casting housings to protect vital equipment. Many electrical parts used in vehicles, machines, and lighting arrangement are enclosed in housings made from aluminum die casting.

- Heat Conductivity: Metals are good conductors of head but not all metal ticks all the boxes when it comes to efficiency and flexibility other than aluminum. The material is cheap and it is highly conductive of heat that is why Aluminum die casting housings can be seen as enclosures for LED lights. All the heat generated by the light is grounded with the help of the housing. Aluminum die casting housing applications can also be seen in outer enclosure of motors and traffic lights and small fans. The main purpose of having those housings is to transfer heat away from the vital operational parts of the application and cool it with the help of air.

- Technological Industry: As technology has grown more and more into a digital sphere, the need for lightweight, portable and durable material has been key to facilitate the upward trend of the technological innovations. So, it should come as no surprise that Aluminum die casting housings are prevalent in the industry as the go to method for protecting vital working areas. While sheet metal is also used in some cases, the durability along with portability offered by aluminum die casting housing is next to no comparison. From large servers to routers used for domestic purposes, Aluminum die casting housings are applied in various types of technological necessities.

- Automobile Industry: One of the major industries to have stepped up their use of Aluminum die casting housings in recent years has been the automobile industry. To be more energy-efficient and curb carbon emissions, automobiles have been shrinking in weight. Carbon fiber for the exterior of the vehicles have been common and same thing is true for use of aluminum parts. From battery shells in EVs to gearbox covers aluminum die casting housings are applied in multiple different parts of a motorized vehicle.

- Communication Industry: This is also a particularly recent trend as communication has grown more and more mobile. With the rise in wireless communications the use of receiving towers, output antennas for 5G communication, fast internet connection have all resorted to use of aluminum die casting housings. But more so even by the handheld and wearable gadget makers who have taken a more impudent step in their bid for light weight devices. There are many phones in the hands of consumers all over the world, that have aluminum die casting housings forming the base of the operation. One of the reasons for this use is for the light weight nature of the material, plus gaming phones tend to get hot frequently, steel retains heat while Aluminum is more in line to dissipate heat from its extremities. This helps in protecting the inside of the device and despite being thin and lightweight, the material is not so brittle, which protects the device from any accidental falls

Smartwatches, fitness tracking devices, television sets, computer parts, there are many devices associated with communication and network functioning that employ the use of aluminum die casting housings.

Why Aluminum Die Casting Housings?

The reasoning for most manufacturers is simple Aluminum die casting housings are sturdy, they are cheap and perform multipurpose function. The characters of Aluminum have much to do with the use of the material for housings. Aluminum is light, no matter the size, compared with other materials observing similar properties. It is also highly conductive of heat and electricity which makes it a special conduit for devices that run hot. Then there is the ease of casting the material itself as well as post-cast machining. There is little to no drawbacks when it comes to Aluminum die casting housings, so it is understandable why almost every industry is utilizing it in one way or the other.

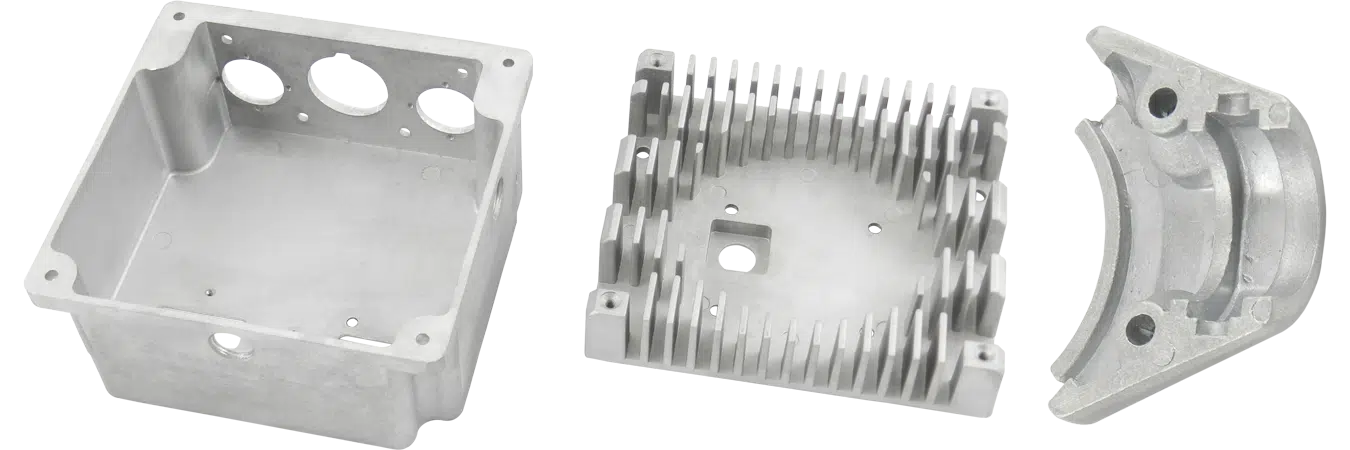

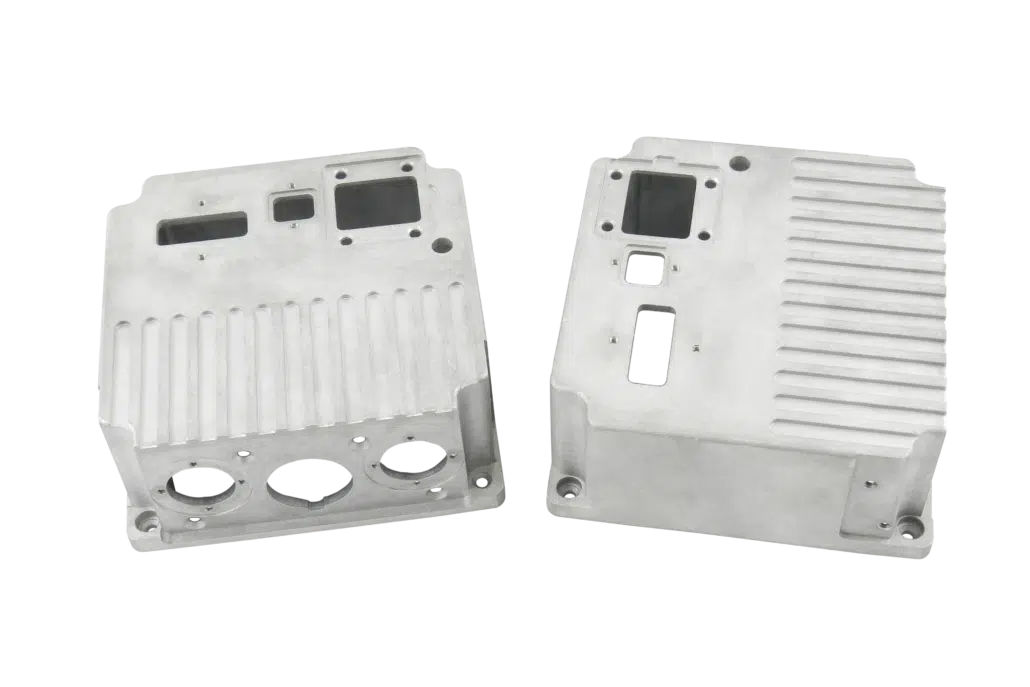

Eurobalt Engineering Has Been Making Aluminum Die Casting Housings

Simple as a block or complex with multiple sinews, holes or crevices, Eurobalt Engineering has been making Aluminum die casting housings for various applications, over the years. High pressure casting machines are used for uniform distribution of molten aluminum. A clamping force of 1250 tons is applied to preserve the wall strength of the housings and even the mold are all produced in house so there is little to no down town in production. We also do all of our machining and when complex design of Aluminum die casting housings requires extra holes in places or refinement after casting, post production machining is all done with certified machines. At Eurobalt Engineering, Aluminum die casting housings are second nature, we built our company making these parts for our customers and we ask you to try it out. Send us your drawings or 3D designs and we would be happy to contact you and come to consensus on how best we can be of service to you. So, drop a line or send us an email!