General Application of Aluminum Die Casting

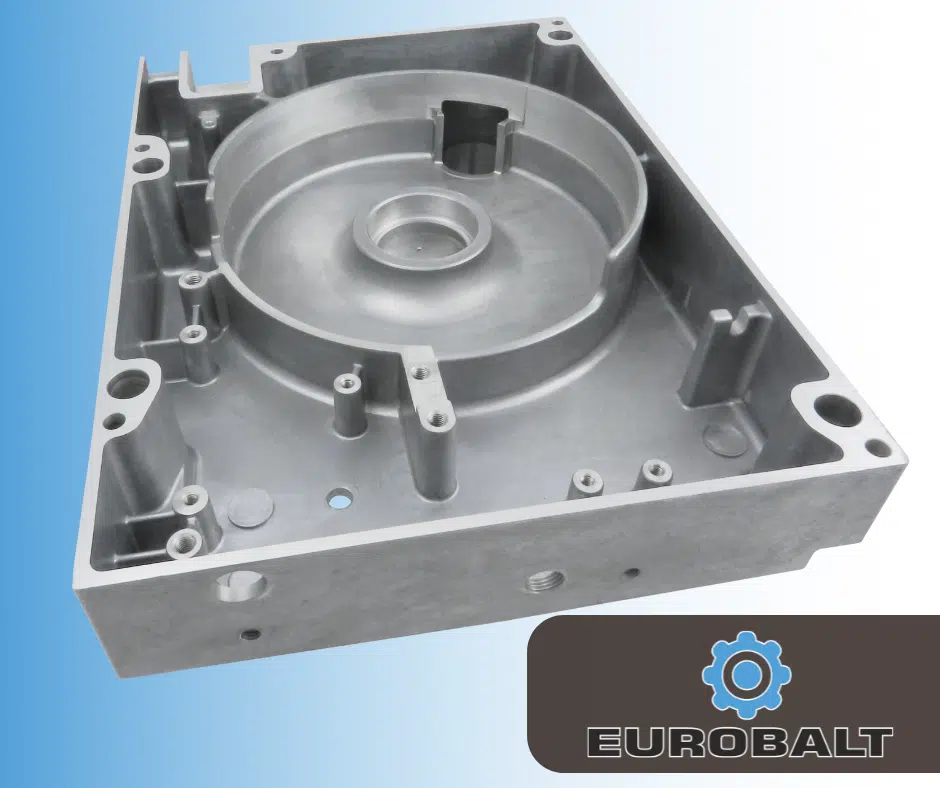

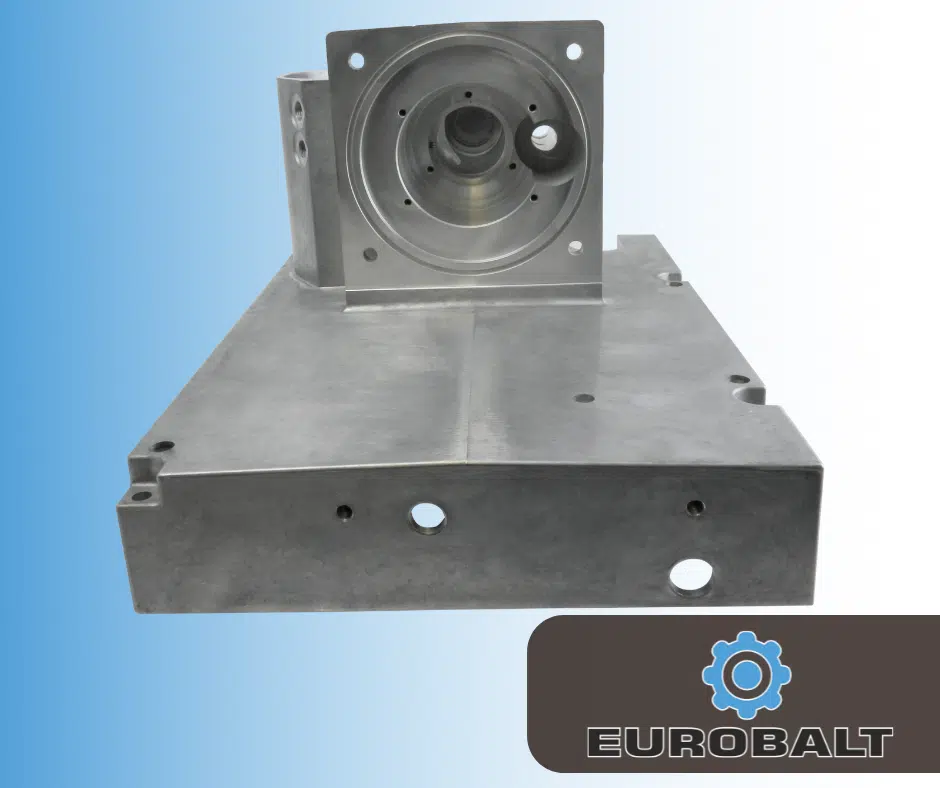

Die Casting is a time-honored manufacturing process with roots dating back thousands of years, but the modern form of casting traces its roots to the mid-19th century. The development of faster moving vehicles and die casting were in lockstep with the use of aluminum as a primary alloy coming later. Aluminum die castings have since become the dominant die castings produced.

While zinc and other alloy castings are also used depending on the properties required by a particular machine where it is to be installed. There are clear reasons why aluminum die castings are preferred for most applications. They are lightweight, dimensionally stable, highly conductive of heat and electricity, and extremely resistant to corrosion. Finding all these qualities in one is why the application of aluminum die castings is so vast.

Application of Aluminum Die Casting

There are number of gadgets in your home, office, transportation and surrounding that uses, to some extent, aluminum die casting parts. But depending on their market share and dominance in certain sectors, here are few applications of aluminum die casting;

Alternatives to Aluminum Die Casting

One of the biggest competitors to aluminum die casting in recent years has been the emergence of 3D printing. With each passing day, larger and finer 3D printed parts are being seen online and in the marketplace. These types of additive processes, which do not even require a mold, can be a serious contender to replace aluminum die casting.

Now there is a case to be made for the rendering power, reusability, and overall affordability of 3D printing. Household 3D printing machines have been made, but they are limited by size. A simple rendering of a part takes anywhere from 3 to 36 hours. Then there is the cost of the material itself, just like paper printers where toner and ink will break you, 3D printing is no different.

The speed of aluminum die casting and the uniformity of each part at the same rate is something we have not seen with 3D printing. Technology is always a long game, it takes time to perfect and be efficient, but right now your safest bet for consistent quality parts with great properties is still aluminum die casting.

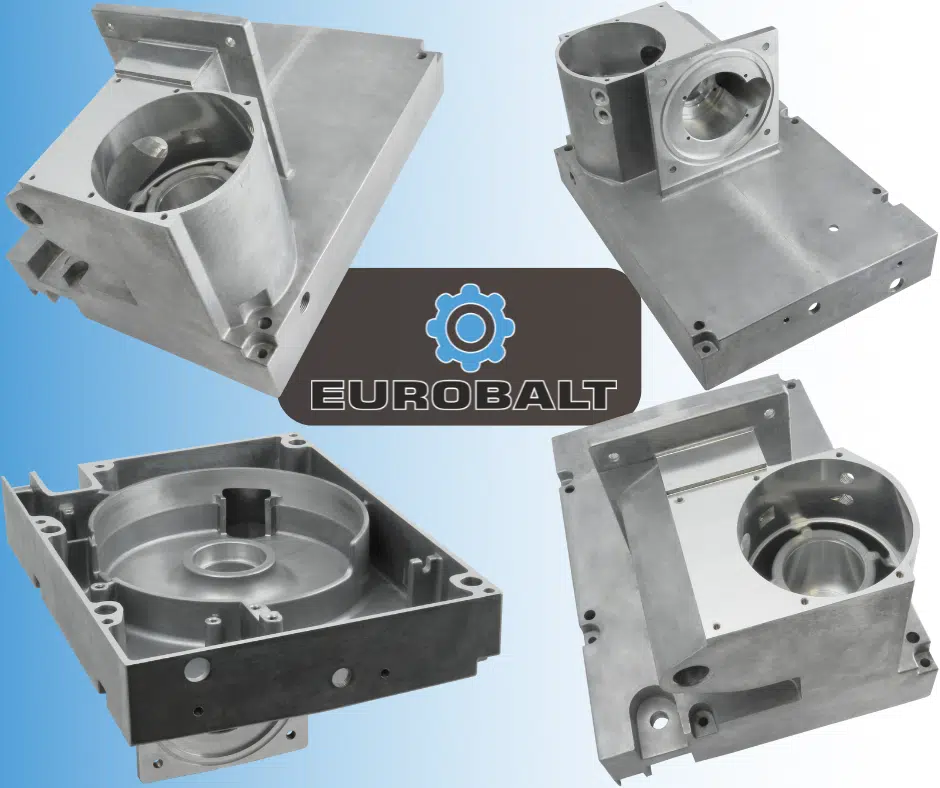

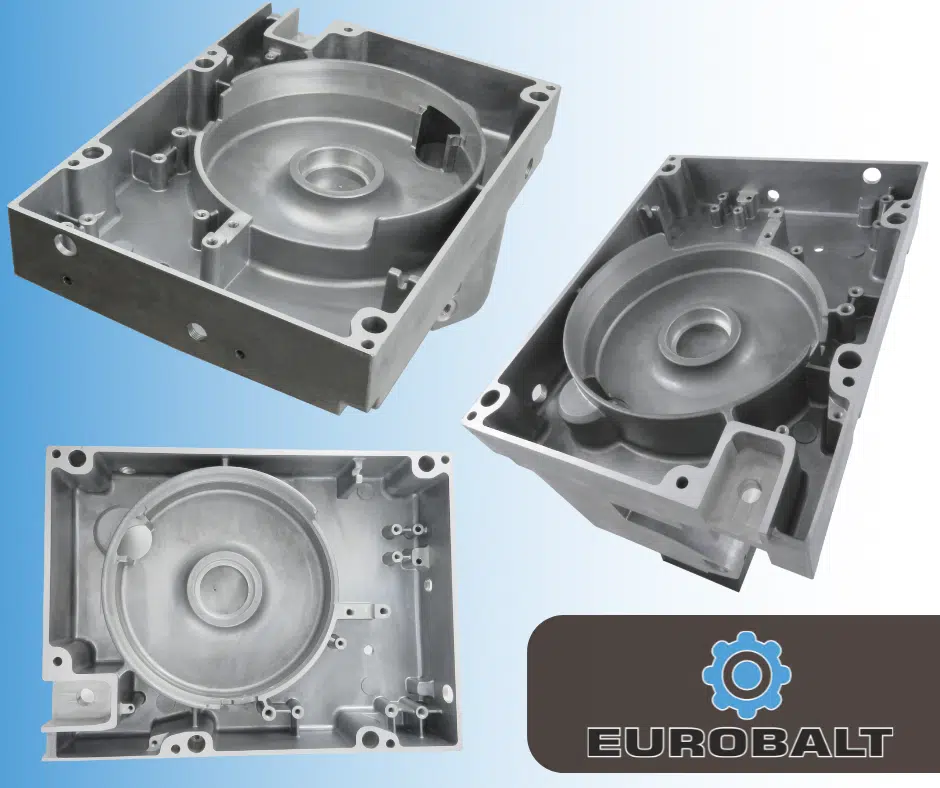

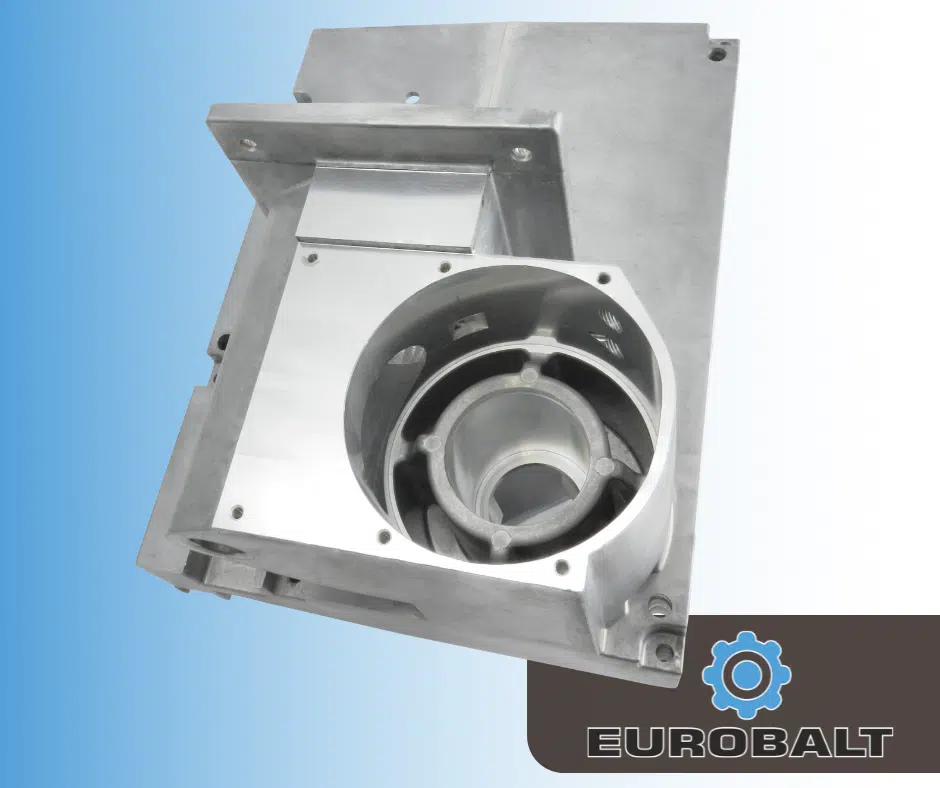

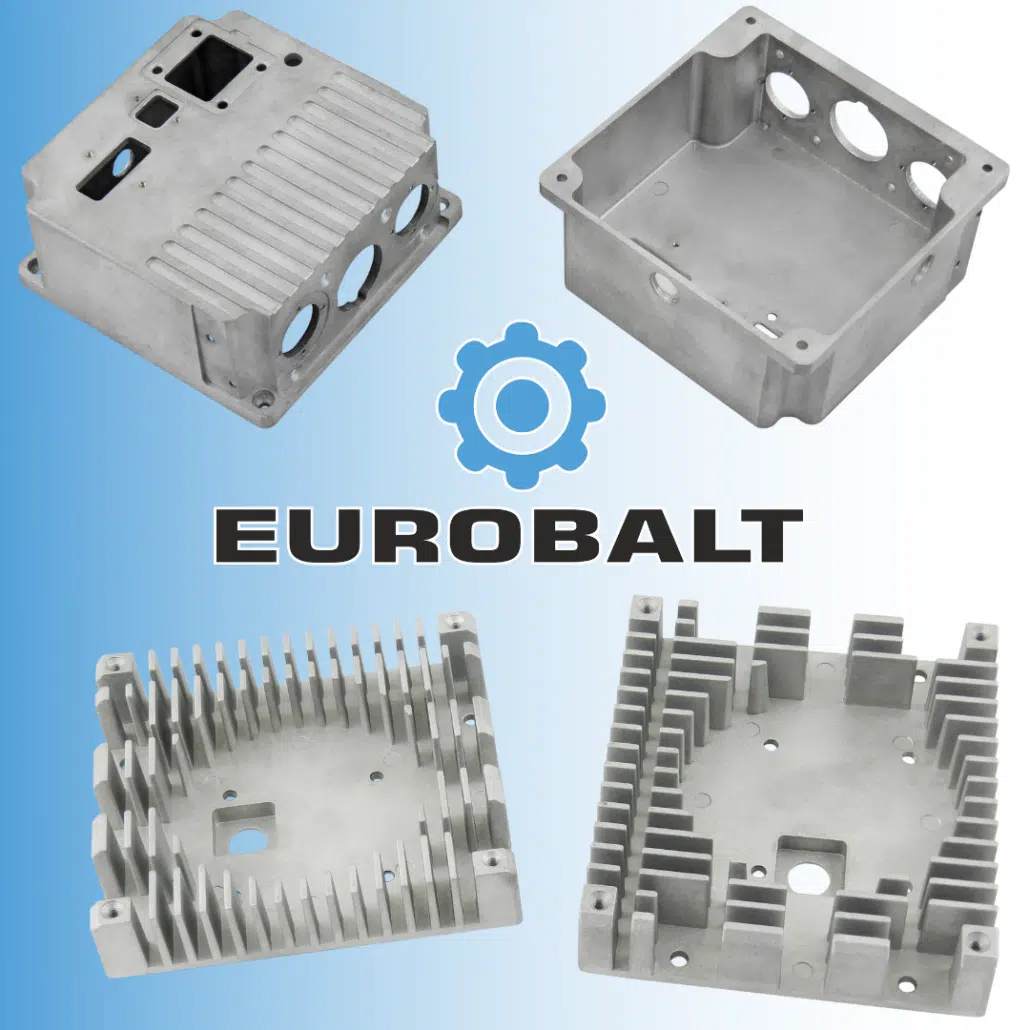

Eurobalt is Continuing its Aluminum Die Casting Work

At Eurobalt we offer different technologies to different customers depending on their requirements. But with the current market needs and feedback from our customers, it seems there is a real need for a good and reliable aluminum die casting supplier. We have been doing it since the establishment of the company, and until the end of 2022, we are only increasing our production in this field.

So, if any of the application of aluminum die casting from above fit your needs, then send us an email or call. Even if the application does not fit you perfectly, send us your requirements and we will let you know if aluminum die casting is the right direction for your manufacturing, we may even suggest other avenues, something that will be better suited to your needs. But first contact us and one of our sales managers will help you in your aluminum die casting parts production needs.