Axial hydraulic pumps

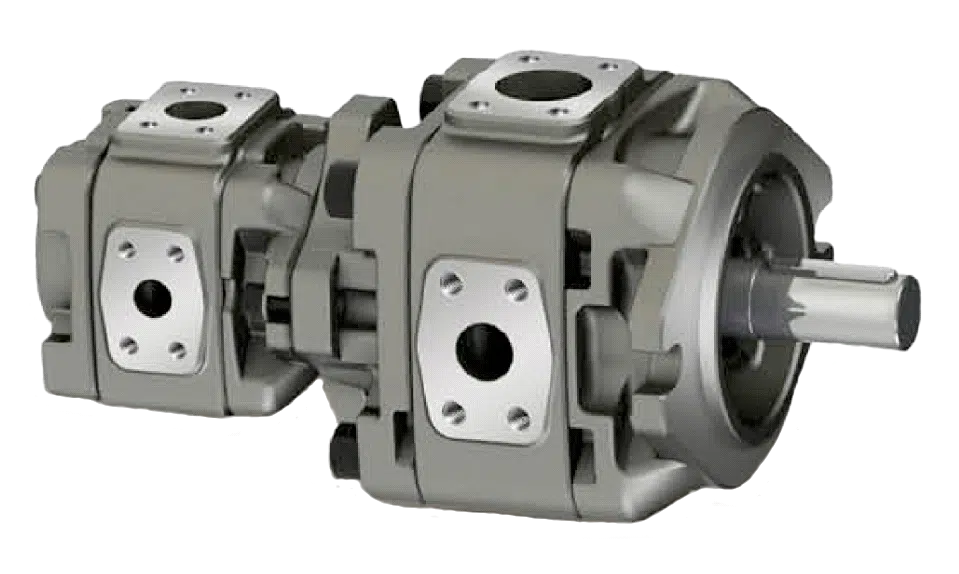

Axial hydraulic pumps are mechanical devices that use a rotating motion to convert energy into fluid flow. They work by using a series of gears or vanes to move a fluid through a system, and they are used in a wide range of applications, from industrial machinery to aircraft braking systems. Eurobalt has been making hydraulic equipment for almost 8 years now and recently the company has expanded its business to provide complete hydraulic solutions. That includes providing hydraulic pumps and motors along with high quality cylinders. One of the pumps currently being manufactured by Eurobalt Engineering are Axial Hydraulic Pumps which we will go further in detail here.

Working Mechanism of Axial Hydraulic Pumps

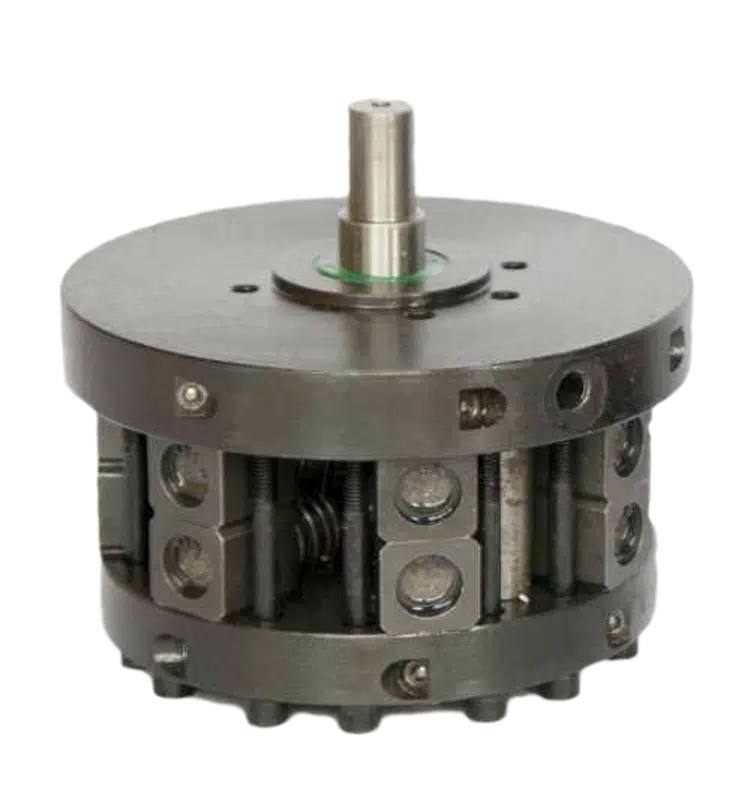

An axial hydraulic pump operates by using a series of gears or vanes to move a fluid through a system. The pump consists of a housing with a central shaft running through it, which is connected to a drive motor or other power source. At one end of the shaft is a series of gears or vanes, which are used to pump the fluid.

As the shaft rotates, the gears or vanes move the fluid through the pump by creating a series of pockets or chambers. These pockets are filled with fluid as they move past the inlet port, and as the gears or vanes continue to rotate, the fluid is pushed out of the pockets and through the outlet port. The fluid is then forced through the system, creating flow and pressure.

There are several types of axial hydraulic pumps, including gear pumps, vane pumps, and lobe pumps. Each of these pumps works slightly differently, but the basic principles of operation are the same. Gear pumps use meshing gears to move the fluid, while vane pumps use a series of sliding vanes to create fluid flow. Lobe pumps use two lobes that rotate against each other to pump the fluid.

Overall, axial hydraulic pumps provide wide range of applications, efficiently and effectively. They are able to transfer energy with minimal loss, and they are capable of moving fluids over long distances and at high pressures. While they may not be suitable for use in applications requiring high accuracy or precise flow control, they are an effective and reliable choice for many industrial and mechanical applications. The advantages and disadvantages determine the use and effective application of axial hydraulic pumps for various industries.

Some of the Advantages of Axial Hydraulic Pumps are as follows;

And as with all things in the world, Axial Hydraulic Pumps also comes with its own sets of disadvantages. One of the main disadvantages of axial hydraulic pumps is that they are not suitable for use in applications where high accuracy or precise flow control is required. They are also not as effective at moving thick or viscous fluids as other types of pumps. Additionally, they may not be as efficient at moving fluids at low speeds or low pressures as other types of pumps.

Overall, axial hydraulic pumps are highly efficient and versatile devices that are well-suited for use in a wide range of applications. They have a simple design, are relatively inexpensive to purchase and operate, and are known for their durability and long service life. While they may not be ideal for use in applications requiring high accuracy or precise flow control, they are a reliable and effective choice for many industrial and mechanical applications.

Eurobalt are Axial Hydraulic Pumps Manufacturer

Eurobalt has 7 years of experience in the manufacturing hydraulic equipment. Over the years, the company has developed a reputation for providing high-quality products and exceptional service to its customers. Eurobalt is known for its flexible pricing, which allows it to offer competitive prices for its products while still maintaining a high level of quality. Competitive prices are a collaborative effort where the client details their needs and we provide they best possible solution at the price point. And that has allowed us to maintain an honest relationship of collaboration and continued communication with our clients.

One of the key advantages of Eurobalt as a manufacturer of axial hydraulic pumps is its timeliness. The company has a reputation for delivering products on time and meeting its customers’ deadlines. This is achieved through the use of advanced production techniques and an efficient supply chain management system. Eurobalt also has a team of highly skilled and experienced engineers who are dedicated to ensuring that the products they manufacture meet the highest standards of quality and performance.

Another advantage of Eurobalt is its effectiveness. The company has a track record of producing high-quality axial hydraulic pumps that are reliable and durable. Its pumps are designed to operate efficiently and effectively in a wide range of applications, and they are tested extensively to ensure that they meet the highest standards of performance. Eurobalt’s pumps are also backed by a comprehensive warranty, which provides customers with added peace of mind and protection.

In addition to its timeliness and effectiveness, Eurobalt is also known for its exceptional customer service. The company’s customer service team is dedicated to helping customers find the right product for their needs and assisting them with any questions or concerns they may have. Whether customers need technical support, installation assistance, or simply have a question about one of Eurobalt’s products, the company’s customer service team is always available to help.

Overall, Eurobalt is a highly respected and reliable manufacturer of axial hydraulic pumps. With 7 years of experience in the field and a track record of producing high-quality products, Eurobalt is well-positioned to meet the needs of its customers. Its flexible pricing, timeliness, effectiveness, and exceptional customer service make it an excellent choice for those in need of high-quality axial hydraulic pumps. So, give us a call or send us an email with all your requirements and we would be glad to be of some assistance.