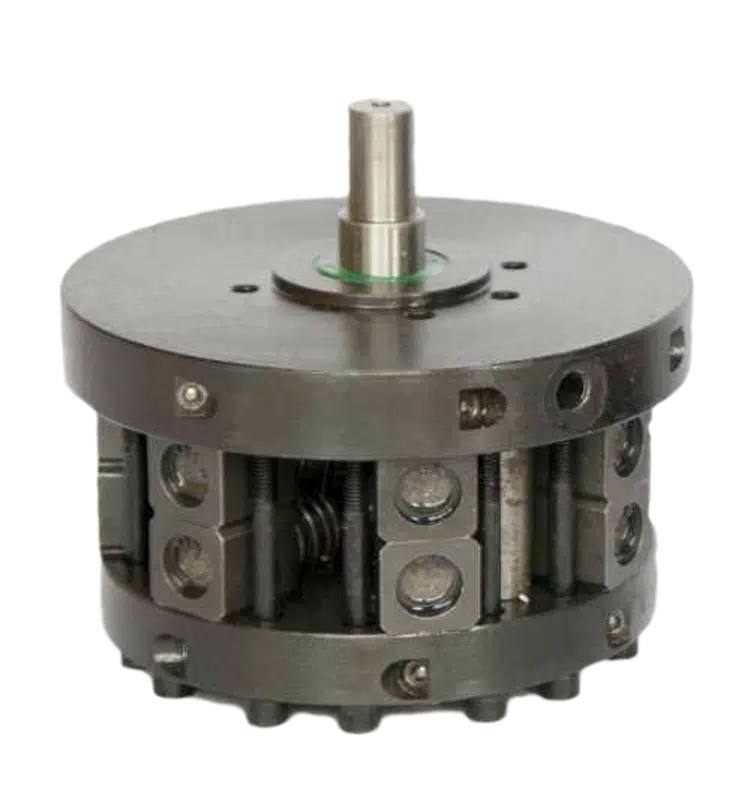

Radial Hydraulic Pump

Radial hydraulic pump is a type of positive displacement pump that moves fluid through the pump with the help of a rotating impeller. The impeller is typically made of a series of vanes that are arranged around a central shaft in a radial pattern. As the impeller rotates, the vanes trap fluid and move it radially outward, where it is then discharged from the pump.

Working of a Radial Hydraulic Pump

A radial hydraulic pump operates by using the rotation of an impeller to move fluid through the pump. When the impeller rotates, the vanes trap fluid and move it radially outward, creating a high level of shear within the fluid. The internal pressure and rotation within the fluid helps to break up any viscosity and makes it easier to pump. As the vanes rotate, they create a series of pockets that move towards the pump outlet. And when these pockets reach the outlet, they are discharged, with new fluid drawn in to fill the empty pockets.

With each rotation a specific volume of fluid is trapped within the impeller and the pump displaces the said volume of fluid every time, this is why radial pumps are one of the types of positive displacement pumps. Because of this, radial hydraulic pumps are often used in applications where high flow rates and moderate pressures are required.

The radial hydraulic pumps are typically driven by an electric motor or a hydraulic motor. The fluid enters the pump inlet and is directed by an inlet guide vane to the impeller, the vanes of the impeller then trap the fluid and throw it radially outward. As the fluid is thrown out, it creates a vacuum in the impeller, causing more fluid to be drawn into the pump.

The outlet of the pump is typically connected to a pipe or hose that carries the fluid to the next point in the system. Depending on the application, the fluid may be used to power a machine or to cool and lubricate parts of the machine.

Radial hydraulic pumps are often used in applications where high flow rates and moderate pressures are required. They are also known for their ability to handle viscous liquids, as well as for their relatively low noise and vibration levels. Radial hydraulic pumps are typically used in a wide range of industrial applications, including construction, mining, and manufacturing. They are also commonly used in mobile equipment such as excavators, cranes, and bulldozers

Advantage of Radial Hydraulic Pumps

When selecting hydraulic pumps for specific industry and pumping needs, there are wide range of functionality and liquid properties to keep in mind. Most of the pumps have the same function, to increase the flow rate of input fluid but knowing the advantages of specific types of pumps can help in the overall quality of the application. So, here are some advantages of using radial hydraulic pumps to take into consideration;

Eurobalt for your Radial Hydraulic Pump Needs

Eurobalt is a supplier of radial hydraulic pumps that is known for its reliability and quality. We offer a wide range of radial hydraulic pumps that are suitable for various industrial and mobile applications.

One of the key features of Eurobalt Engineering’s radial hydraulic pumps is our maximum flow range of 25 liters per minute. This high flow rate makes us suitable for applications where a large amount of fluid needs to be moved quickly and efficiently.

Another key feature is the maximum rotation speed of up to 2000 RPM. This high rotation speed allows the pump to move a large volume of fluid in a short amount of time, which is ideal for applications where speed is a critical factor. In addition, Eurobalt Engineering’s radial hydraulic pumps can operate at pressures of up to 50 MPa. This high operation pressure makes them suitable for applications where a high level of force is required to move the fluid.

Eurobalt radial hydraulic pumps are also known for their durability and longevity. The pumps are made of high-quality materials and are designed to withstand the rigors of industrial and mobile applications. The company also offers after-sales services and spare parts, which ensures that the pumps continue to operate at optimal performance.

We offer variety of pumps and motors depending on the fluid moving need as well as the type of fluid being moved by our clients. Axial hydraulic pumps fall within our portfolio of replacement level pumps of name brands at a price point that is unmatched by most other European suppliers. So, a triple threat of durability, market beating price and after sales service make Eurobalt Engineering an unique proposition when searching for your next radial hydraulic pump. Nothing else to do now other than pick up the phone and give us a call or write an email, and a sales representative will take care of all your radial hydraulic pump needs.