The Advantages and Challenges of Sintered Gears in Transmission

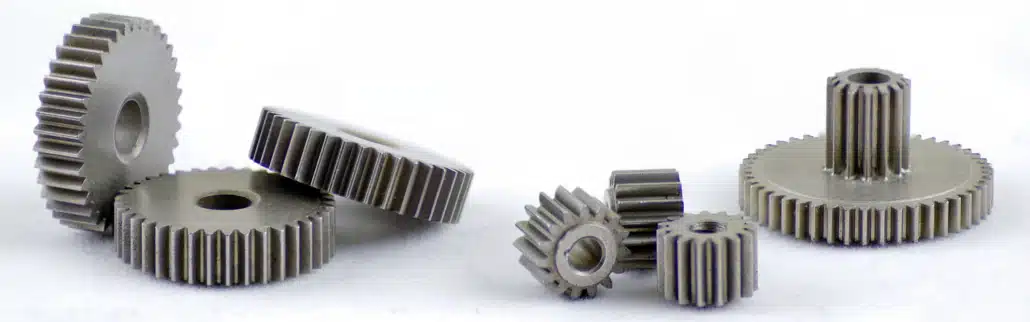

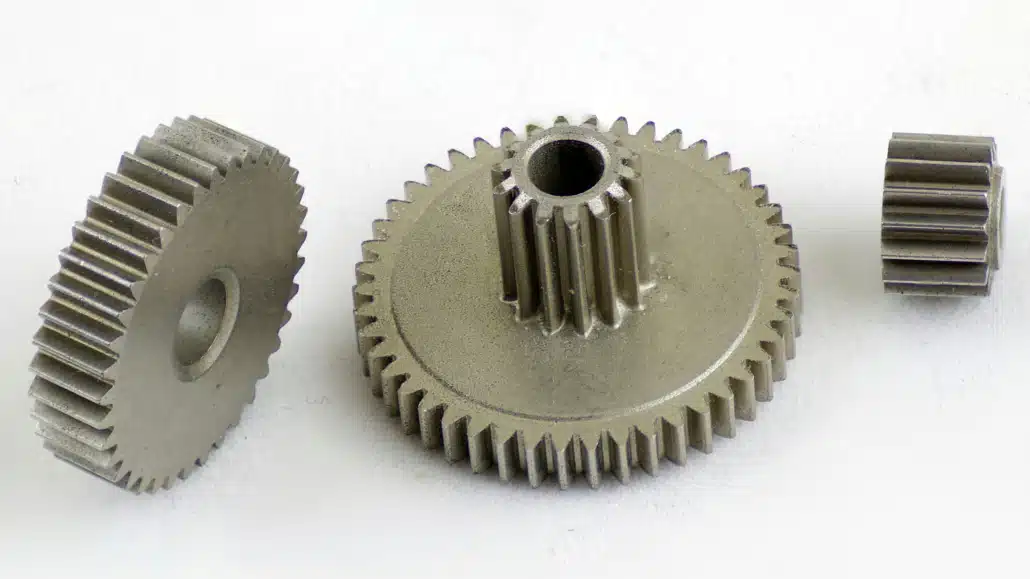

Sintered gears have emerged as a reliable and cost-effective solution in various industries, particularly in transmission systems. These gears are created using a process called powder metallurgy, which offers unique benefits and challenges. In this article, we will explore the advantages and drawbacks of utilizing sintered gears in transmission, their impact on manufacturing costs, quality, and performance, as well as safety concerns associated with their implementation.

Benefits of Sintered Gears:

Drawbacks and Challenges:

Safety Concerns and Contamination Risks:

Applications and Performance:

Sintered gears find applications in a wide range of equipment, including automotive transmissions, power tools, industrial machinery, and consumer appliances. For example, in automotive transmissions, sintered gears have improved fuel efficiency and reduced noise levels, contributing to smoother gear shifting and enhanced overall performance.

Sintered gears offer several advantages such as cost-effective manufacturing, enhanced material properties, and increased design flexibility. However, their inherent challenges, including porosity, limited load capacity, and potential contamination risks, must be carefully considered in the design and application process. With proper selection, manufacturing, and quality control measures, sintered gears can significantly improve the performance and efficiency of transmission systems, benefiting various industries.

With years of experience in the industry, Eurobalt has established itself as a leading manufacturer and supplier of sintered gears. Our gears are produced using advanced powder metallurgy techniques, ensuring excellent material properties, precise tooth profiles, and reliable performance.

Ordering from Eurobalt is quick and easy. Simply contact our sales team at +372 650 60 96 or office@eurobalt.net. Our dedicated professionals will assist you, answering any questions you may have.

Don’t miss out on the opportunity to elevate your transmission systems with high-quality sintered gears from Eurobalt.

References: - Lin, T. et al. (2017). Sintered Metal Gears: New Progress and Latest Application. Key Engineering Materials, 737, 338-343. - Somashekhar, S. H. et al. (2019). Manufacturing and Performance Evaluation of Sintered Steel Gear. International Journal of Engineering Research & Technology, 8(02), 1017-1022. - Chawla, N. et al. (2019). Design of Sintered Gears for a Two-Wheeler Transmission System. Materials Today: Proceedings, 18, 2707-2714.