Enhancing Productivity and Quality: Eurobalt’s Metal Parts for Industrial Applications

Welcome to Eurobalt, a trusted manufacturer renowned for producing high-quality metal parts for a wide range of industrial applications. In this article, we proudly present an overview of our exceptional metal shafts: the Flat Shaft and the Long Shaft. Discover the meticulous craftsmanship and precision engineering behind these products as we delve into their manufacturing processes and showcase their remarkable features. Join us on this journey of innovation and reliability in industrial manufacturing.

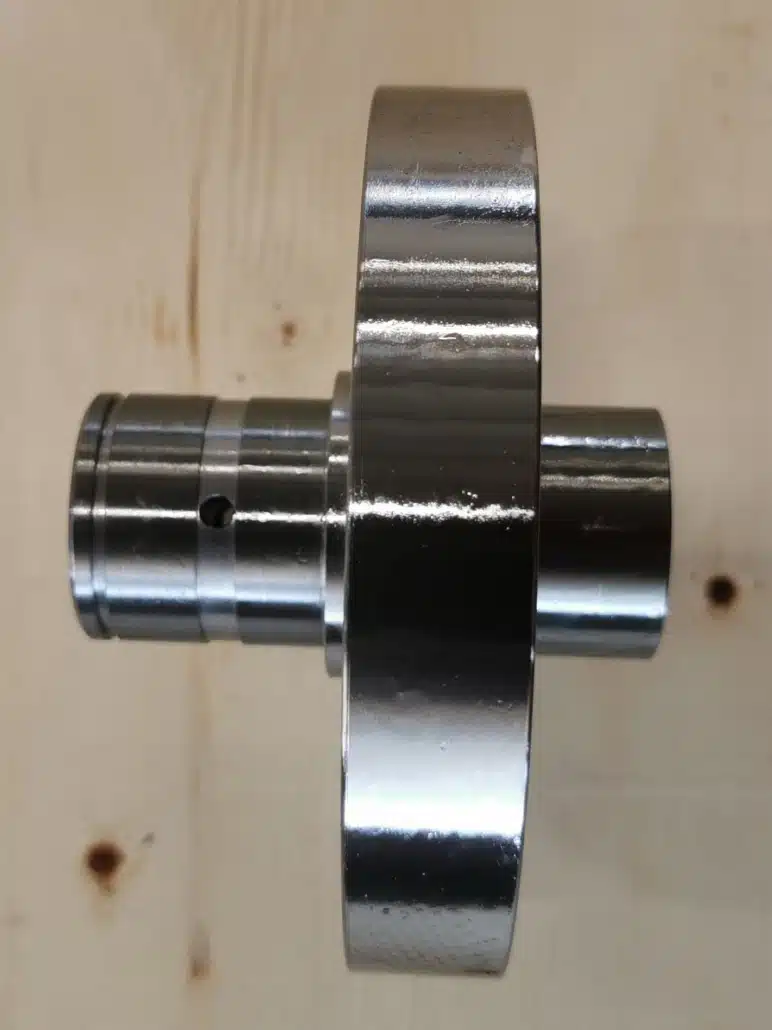

I. Flat Shaft: Engineering Excellence at its Finest

The Flat Shaft stands as a testament to Eurobalt’s commitment to excellence. Crafted from top-grade Steel 45, this robust component boasts impressive dimensions: a large diameter of 120mm, a length of 78.5mm, and a main diameter of 35mm (g6). With a weight of 2.07kg, it offers superior strength and durability. Be captivated by its sleek design and flawless precision.

II. Long Shaft: Power and Performance Redefined

The Long Shaft is an engineering marvel, meticulously designed and manufactured to meet the highest industry standards. Fabricated from premium 18NiCrMo5 material, this shaft undergoes a precise carburizing process to achieve a thickness of 0.6mm and an impressive hardness of 57-58 HRC. With a length of 119mm, a shaft diameter of Ø35 (f6), and an outer part measuring 60x60mm, this lightweight component weighing 1.07kg exhibits exceptional performance and endurance.

III. Manufacturing Process: Unleashing Innovation and Precision

At Eurobalt, our manufacturing process is a testament to our unwavering commitment to quality and precision. Each metal shaft undergoes a meticulous journey, ensuring the highest standards of craftsmanship are upheld:

Raw Material Selection: We handpick the finest materials, guaranteeing superior durability and performance.

Thermal Treatment: A carefully controlled heat treatment process ensures dimensional stability and mechanical integrity.

CNC Machining: State-of-the-art CNC machines expertly shape and refine the metal shafts, ensuring unrivaled accuracy and consistency.

Precision Grinding: Our skilled technicians employ cutting-edge grinding techniques, delivering exceptional surface finish and dimensional accuracy.

Dimensional Inspection: Rigorous inspections employing advanced measurement tools ensure strict compliance with dimensional tolerances, guaranteeing the utmost precision and quality.

Lubrication and Packaging: Prior to packaging, each component undergoes meticulous lubrication, optimizing its performance and longevity during operation.

IV. Unleashing the Potential: Application and Assembly

The Flat Shaft and Long Shaft are engineered to elevate industrial applications to new heights. With their exceptional dimensional accuracy and precise tolerances, these metal shafts seamlessly integrate into diverse industrial environments:

Bearing Installation: The meticulously designed shafts accommodate ball bearings on both ends, ensuring smooth rotation and optimal performance.

Component Fastening: Secure attachment to industrial structures is achieved through strategically positioned holes that allow for precise bolt placement, enabling robust and reliable assembly.

Eurobalt takes immense pride in manufacturing top-quality metal parts that surpass industry expectations. Our Flat Shaft and Long Shaft embody the perfect balance of innovation, precision, and durability, making them indispensable components in various industrial applications. Trust Eurobalt for unparalleled craftsmanship, unwavering quality, and unmatched reliability.

Discover the power of Eurobalt’s metal parts – the foundation of your industrial success. Contact us today to explore how our cutting-edge solutions can elevate your operations to new horizons.