Gear pumps for agricultural machines

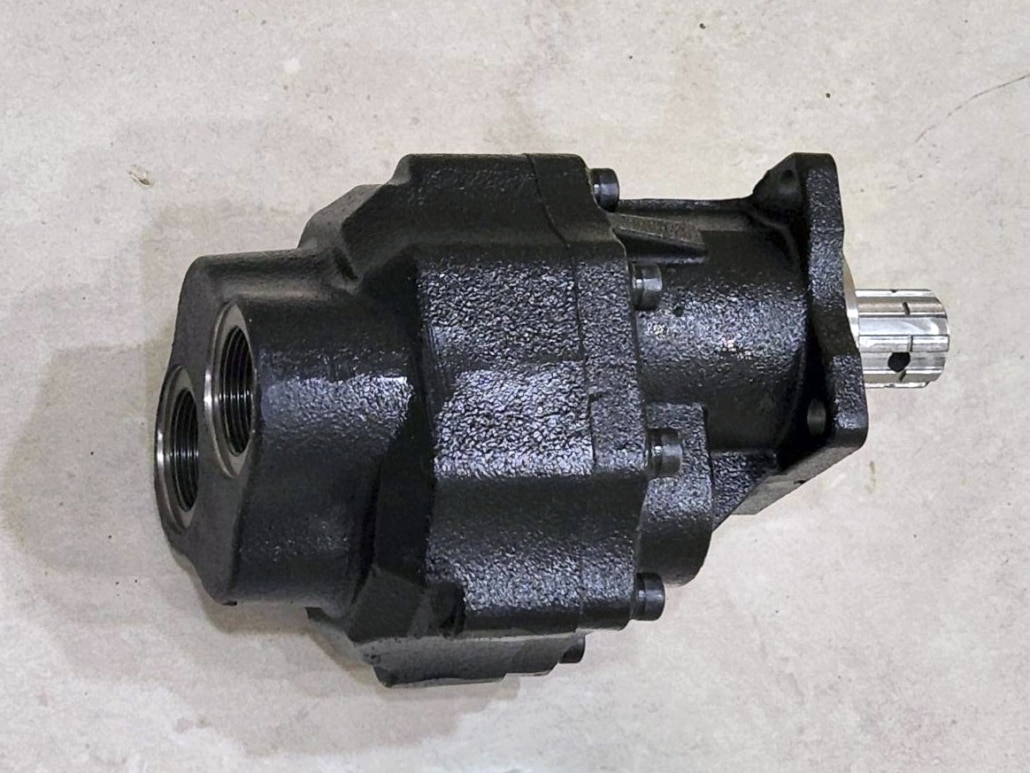

Gear pumps are positive displacement pumps commonly used in a variety of industrial applications to transfer fluids. Because of their efficiency, reliability and precise fluid delivery, gear pumps are trusted for a wide variety of applications. Gear pumps primarily consist of two intermeshing metal gears housed in a casing. When power is applied to gear pumps, the intermeshing gears rotate in opposite directions, creating vacuum chambers between the gears and the housing, allowing fluid to enter and exit the pump.

The gear pump operates when fluid is drawn into the vacuum created by the intermeshing gears as they rotate. The fluid is then carried to the discharge port as the previously vacuumed portion of the gear seals the fluid between the gear and the housing. Because the gears are precision machined, they do not allow backflow and the continued meshing ensures that the fluid is pushed toward the outlet. This displacement mechanism provides a steady flow of fluid with minimal pulsation.

Gear pumps offer several advantages over other types of pumps:

Despite their many advantages, gear pumps also have some limitations

Despite the limitations, there are more and more industries that use gear pumps in their machinery for their pumping needs. One such industry that relies heavily on pumping fluids, lubricants and power transmission is the agricultural industry. The precision and reliability of gear pumps make them ideal for use in agricultural machinery. Some of the agricultural machines that use gear pumps are listed below;

At Eurobalt, we have been meeting the needs of our customers for hydraulic pumps for some time now. One of our areas of expertise is gear pumps, and we have seen a lot of movement in the market for gear pumps used in agricultural machinery. And because of several key factors, we are the ideal manufacturer for your hydraulic pump needs. Here are a few reasons why we are the best choice for your gear pump needs:

We are a customer-first company where your satisfaction is our primary goal. When you purchase one of our pumps, we provide after sales service, engineering consultation and product warranty so you have nothing to worry about. Our customer-centric approach is why customers come back to us for advice on their entire hydraulic system. This trust and confidence is why we continue our efforts to reach more customers and provide them with the solutions they need in their machine. In the meantime, if you are looking for a reliable gear pump supplier, please contact us.