Custom Manufacturing of Mixer Parts

Precision and Quality in Every Component

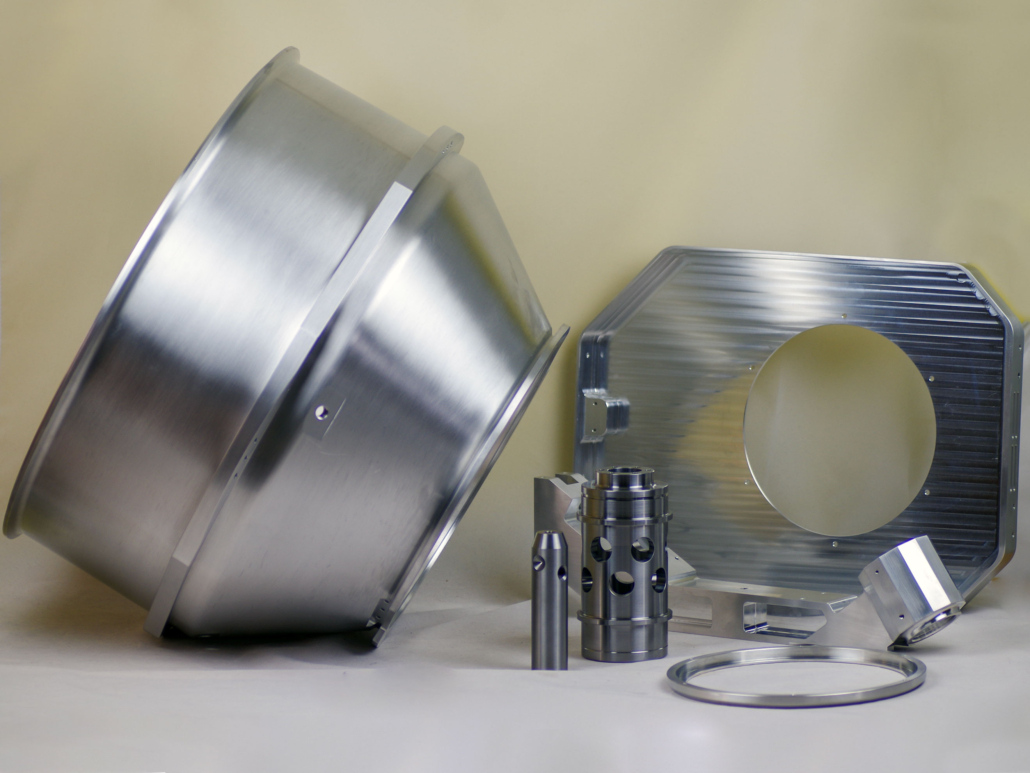

At Eurobalt, we take pride in our ability to deliver high-quality, custom-manufactured parts for a wide range of industrial applications. Recently, we completed an exciting project that involved the production of a comprehensive set of components for an industrial mixer. This article details the process and highlights the precision and expertise involved in creating these parts.

Project Overview

The project required us to manufacture several critical components for an industrial mixer, each designed according to the customer’s detailed drawings and specifications. Our team of experts utilized state-of-the-art machinery and advanced manufacturing techniques to ensure that every part met the highest standards of quality and performance.

Key Components Manufactured

Precision-Machined Solid Drum

- Material: High-strength alloy

- Features: The drum was meticulously machined from a single piece of metal to ensure uniformity and strength. The precise machining process guarantees the drum’s durability and optimal performance in mixing operations.

Perfectly Fitted Lid

- Material: Matching alloy

- Features: The lid was crafted to perfectly fit the solid drum, ensuring a tight seal and efficient operation. The precision in the lid’s manufacturing ensures compatibility and ease of use.

Special Alloy Sleeves

-

- Material: Custom special alloy

- Features: These sleeves were designed to withstand high wear and tear, providing longevity and reliability. The use of a special alloy ensures that the sleeves perform well under demanding industrial conditions.

Additional Custom Components

- Other Parts: Various custom parts were also manufactured, including mixing blades, shafts, and support structures. Each part was designed with specific functionalities in mind, ensuring they work seamlessly together within the mixer.

Manufacturing Process

The manufacturing process involved several key steps:

Design and Planning

- Our engineering team worked closely with the customer to understand their requirements and specifications. Detailed drawings and 3D models were created to guide the manufacturing process.

Material Selection

- Selecting the right materials was crucial for this project. High-strength alloys were chosen for their durability and performance under industrial conditions.

Precision Machining

- Using our advanced CNC lathes and milling machines, each part was machined with the highest precision. This step was critical to ensure that all components met the exact specifications and tolerances.

Quality Control

- Every part underwent rigorous quality control checks. Our quality assurance team used advanced measuring equipment to verify the dimensions and integrity of each component, ensuring they adhered to the customer’s specifications.

Surface Finishing

- The final step involved polishing and finishing each part to meet the strict surface quality requirements. This included achieving a surface polish standard, ensuring that all parts have a smooth, flawless finish.

Conclusion

The successful completion of this project underscores Eurobalt’s commitment to precision, quality, and customer satisfaction. By leveraging our advanced manufacturing capabilities and experienced team, we were able to deliver a complete set of custom parts for an industrial mixer that meets the highest standards of performance and reliability.

If you have a project that requires custom manufacturing of industrial components, contact Eurobalt today. Our team is ready to bring your vision to life with unparalleled precision and quality.