Manufacturing Custom Gear Sets

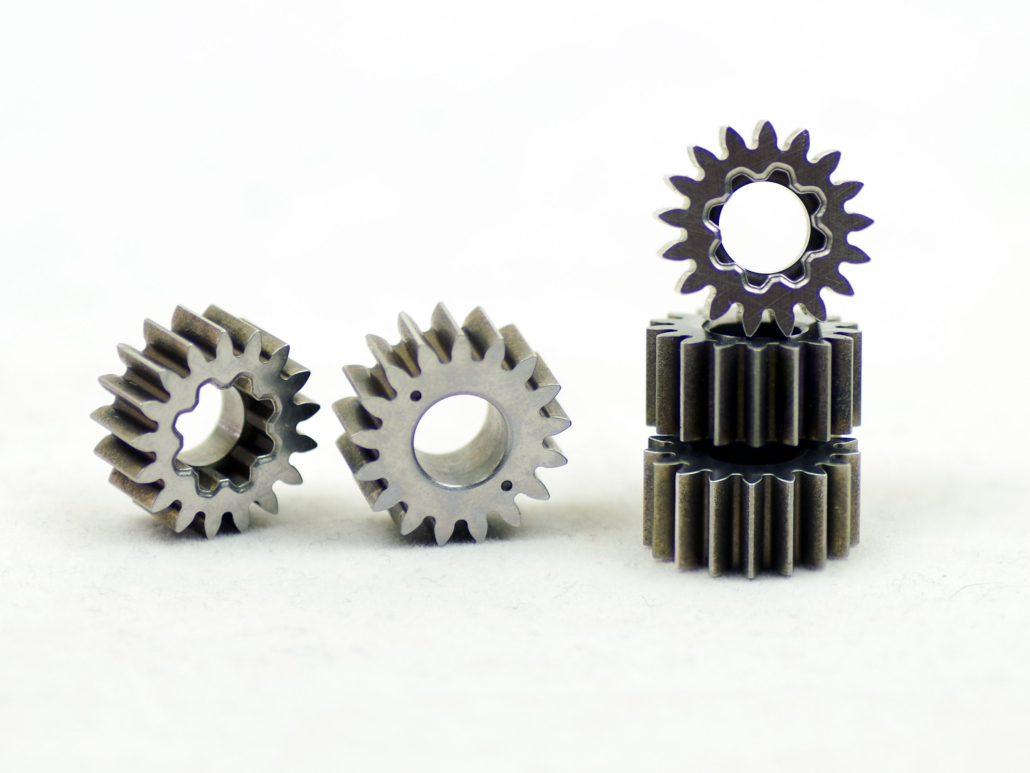

At our facility, we recently completed the production of a set of custom gears. This project involved the creation of 20 samples for each of the five different types of gears, totaling 100 gears.

Project Highlights

Types of Gears Manufactured:

- Outer Rotor

- Weight: 85.64 g

- Material: Sint-D39

- Key Specifications:

- Hardness: >110 HB

- Magnetic field strength: <5 A/cm

- Technical cleanliness: Metallic and non-metallic particles within specified limits

- Anti-rust treatment applied

- Idler Gear

- Weight: 6.29 g

- Material: Sint-D32

- Key Specifications:

- Hardness: >550 HV0.2

- Technical cleanliness: Compliant with ISO 1328:2013 Q8

- Anti-rust treatment applied

- Drive Gear

- Weight: 6.05 g

- Material: Sint-D32

- Key Specifications:

- Hardness: >550 HV0.2

- Technical cleanliness: Adheres to ISO 1328:2013 Q8 standards

- Anti-rust treatment applied

Each gear type was manufactured to meet stringent quality standards, including precise measurements and tolerance levels. Our state-of-the-art equipment and experienced team ensure that each gear meets the specific requirements set forth by our clients.

Production Process

The gears were produced using advanced sinter hardening and tempering processes to achieve the desired hardness and durability. The production involved multiple quality checks to ensure compliance with all technical cleanliness requirements. Anti-rust treatments were applied to prevent corrosion and extend the lifespan of the gears.

Quality Control

Our comprehensive quality control system ensures that every gear produced meets the highest standards. Key aspects of our quality control include:

- Hardness Testing: Ensuring each gear meets the specified hardness level.

- Dimensional Accuracy: Verifying all dimensions are within the specified tolerances.

- Cleanliness: Conducting thorough inspections to ensure all gears are free from unwanted particles.

This project underscores our capability to produce high-quality custom gears in compliance with stringent specifications. Our commitment to quality and precision in manufacturing ensures that we can meet the diverse needs of our clients across various industries. Stay tuned for more updates on our manufacturing capabilities and project achievements.