Die Casting Manufacturing: Comprehensive Capabilities and Distinctive Advantages

Die casting represents one of the most versatile and efficient metal forming processes in modern manufacturing. This precision technique transforms molten metal into complex, high-quality components that serve industries ranging from automotive to electronics, telecommunications to aerospace. Understanding the full spectrum of die casting capabilities helps manufacturers select the optimal approach for their specific applications.

The Die Casting Process: Foundation of Precision

Die casting involves injecting molten metal under high pressure into reusable steel molds, called dies. This process delivers exceptional dimensional accuracy, smooth surface finishes, and the ability to produce intricate geometries that would be challenging or impossible with other manufacturing methods. The high-pressure injection ensures complete cavity filling, capturing even the finest details while maintaining consistent wall thicknesses throughout the component.

The process excels particularly with non-ferrous metals such as aluminum, zinc, and magnesium alloys. Each material brings distinct advantages: aluminum offers excellent strength-to-weight ratios and thermal properties, zinc provides superior casting fluidity and dimensional stability, while magnesium delivers the lightest structural components possible.

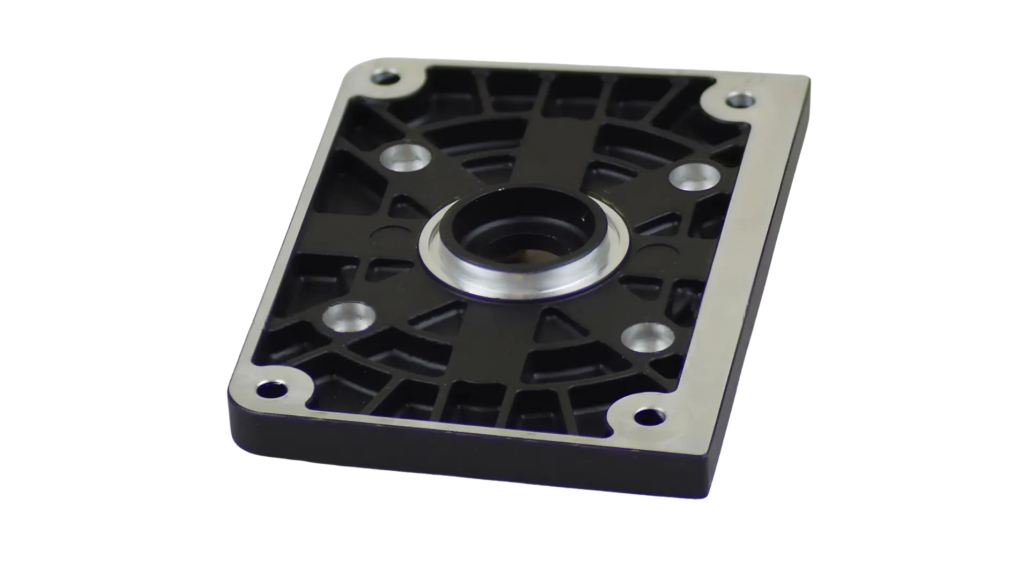

Complex Geometries: Engineering Without Limits

Modern die casting technology enables the production of remarkably complex shapes in a single operation. Components can incorporate multiple functional features including:

- Integrated cooling channels and heat sinks with precisely designed fin arrays for optimal thermal management

- Thin-walled sections down to 0.5mm thickness while maintaining structural integrity

- Undercuts and side-cores that eliminate secondary operations

- Threaded inserts and bosses cast directly into the part

- Complex internal passages for fluid or air flow applications

This capability to combine multiple functions into a single cast component significantly reduces assembly time, minimizes potential failure points, and often results in lighter, more efficient designs.

Surface Treatment Excellence: Beyond the Cast Finish

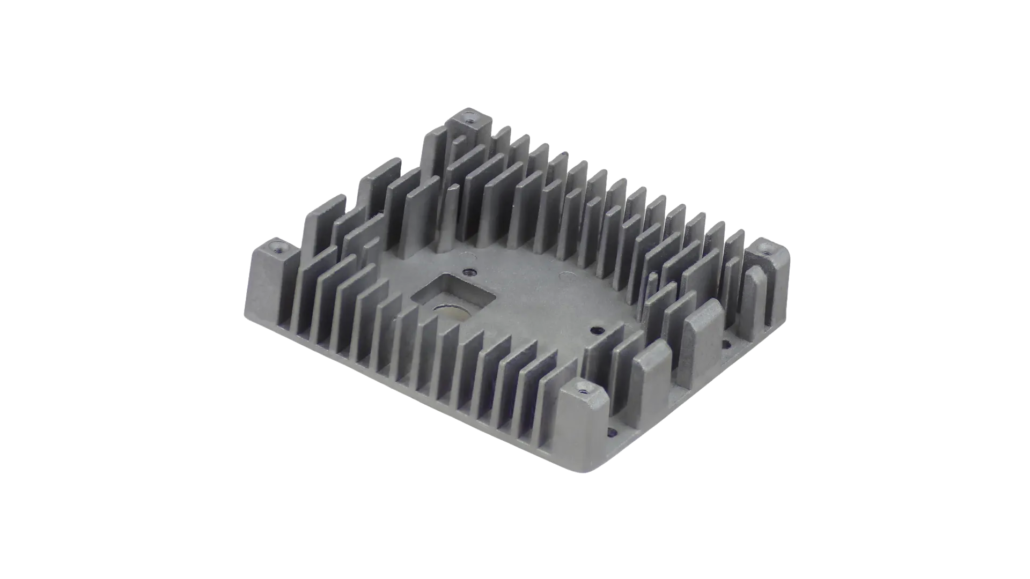

Thermal Management Solutions

Die casting excels in producing components designed for heat dissipation. The process enables the creation of:

- High-density fin arrays with optimal spacing for natural or forced convection cooling

- Variable wall thicknesses that direct heat flow paths

- Integrated mounting surfaces ensuring perfect thermal contact

- Complex internal cooling channels impossible to achieve through machining alone

These thermal management capabilities make die casting the preferred choice for LED lighting housings, electronic enclosures, automotive heat exchangers, and telecommunications equipment where efficient heat dissipation directly impacts product performance and longevity.

Decorative and Functional Integration

Modern die casting bridges the gap between functional engineering and aesthetic design. Components can feature:

- Textured surfaces ranging from fine leather grains to bold geometric patterns

- Logo and text integration cast directly into the part surface

- Multi-level relief designs creating visual depth and interest

- Precision mating surfaces eliminating visible joint lines in assemblies

This versatility allows designers to create products where the housing or structural component becomes an integral part of the product’s visual identity, reducing part count while enhancing overall design cohesion.

Quality Assurance and Consistency

Die casting’s inherent repeatability ensures consistent quality across production runs from hundreds to millions of pieces. Advanced process controls monitor critical parameters including:

- Metal temperature and composition

- Injection pressure and velocity profiles

- Die temperature management

- Cycle time optimization

These controls, combined with statistical process monitoring and automated inspection systems, guarantee that every component meets precise specifications for dimensional accuracy, surface quality, and mechanical properties.

Economic Advantages Across Production Scales

While die casting requires initial tooling investment, the process delivers compelling economics through:

- Rapid cycle times producing finished parts in seconds

- Minimal material waste with net-shape or near-net-shape production

- Reduced secondary operations through integrated features and excellent surface finish

- Extended tool life with properly maintained dies producing hundreds of thousands of parts

- Labor efficiency through highly automated production processes

Choosing the Right Die Casting Partner

Successful die casting projects require collaboration between design engineers and experienced manufacturers. Key considerations include:

Conclusion

Die casting manufacturing continues to evolve, pushing boundaries in component complexity, surface quality, and functional integration. From simple brackets to sophisticated thermal management systems, from decorative housings to precision mechanical components, die casting offers unmatched versatility in metal component production. Understanding these comprehensive capabilities enables manufacturers to fully leverage die casting’s potential, creating products that excel in performance, aesthetics, and economic value.

The combination of advanced die casting techniques with modern surface treatments and finishing options opens endless possibilities for innovative product design. Whether the goal involves optimal heat dissipation, distinctive visual appeal, or complex functional integration, die casting provides the manufacturing solution that transforms ambitious designs into production reality.