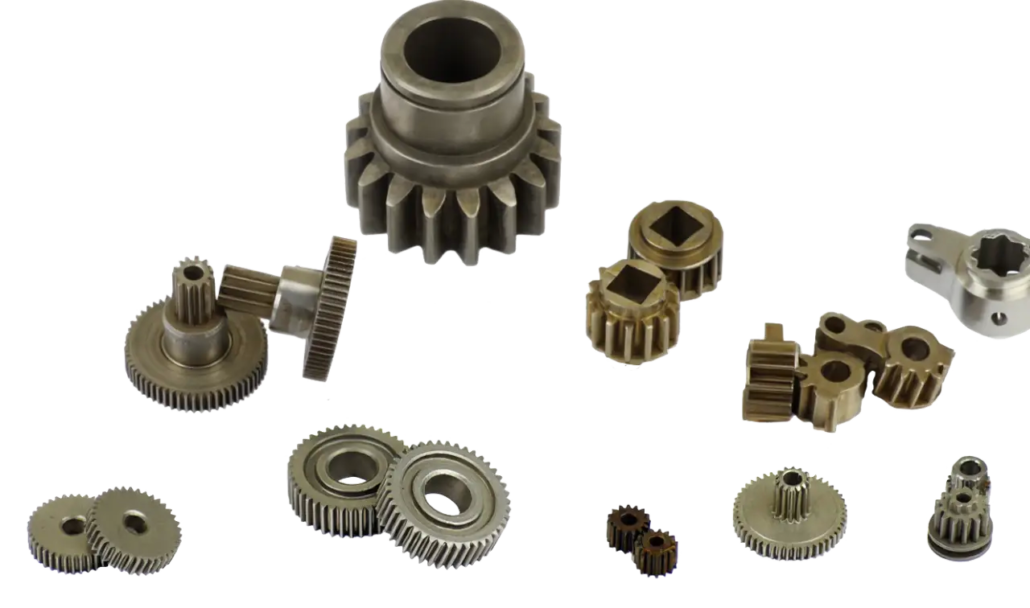

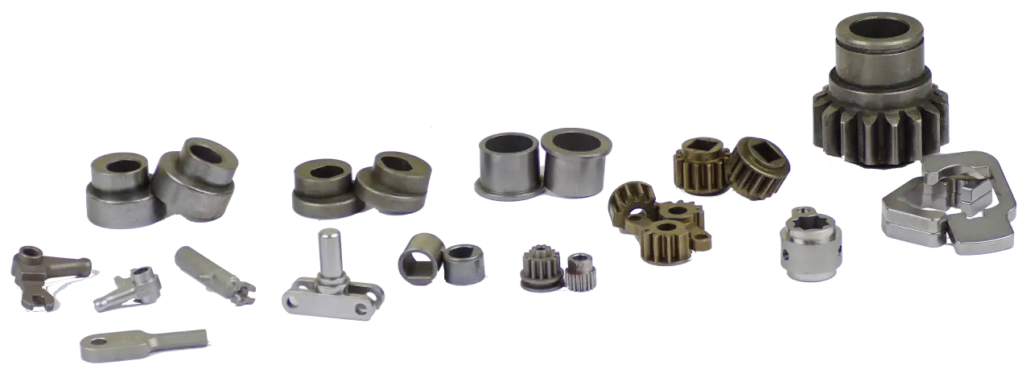

Precision Gear Manufacturing Through Powder Metallurgy: Meeting the Demands of Modern Industry

In today’s precision-driven manufacturing landscape, the production of small, complex gears requires both exceptional accuracy and cost-effectiveness. Powder metallurgy (PM) has emerged as a leading technology for manufacturing high-quality gears used in everything from luxury watches to security locks. At Eurobalt, we specialize in producing precision powder metal gears that meet the exacting standards of various industries while maintaining competitive production costs.

Understanding Powder Metallurgy for Gear Production

Powder metallurgy is a manufacturing process that creates metal parts by compacting fine metal powders in precision dies and then sintering them at high temperatures. For gear manufacturing, this process offers unique advantages that traditional machining methods cannot match, particularly when producing small, intricate components in large volumes.

The process begins with carefully selected metal powders—typically iron, steel, bronze, or specialized alloys—that are blended to achieve specific material properties. These powders are then compressed in precision-tooled dies under pressures ranging from 400 to 800 MPa, forming a “green” compact that holds the exact shape of the desired gear.

The Manufacturing Process: From Powder to Precision

Powder Selection and Blending

The foundation of any quality PM gear starts with the right powder blend. For watch gears, we often use brass or stainless steel powders that offer excellent corrosion resistance and dimensional stability. Lock mechanism gears typically require higher strength materials, such as iron-copper or nickel-steel alloys that provide superior wear resistance.

Compaction

During compaction, the powder is pressed into precision dies that have been machined to tolerances as tight as ±0.025 mm. The gear tooth profile, bore, and other features are formed simultaneously, eliminating the need for most secondary machining operations.

Sintering

The compacted gears are then heated in controlled-atmosphere furnaces to temperatures just below the melting point of the base metal (typically 1100-1300°C for ferrous materials). This process bonds the powder particles together, creating a solid metal component with controlled porosity and excellent mechanical properties.

Secondary Operations

Depending on the application, gears may undergo additional processes such as sizing for tighter tolerances, heat treatment for enhanced hardness, or surface treatments for improved wear resistance.

Applications in Watchmaking

The watchmaking industry demands gears of exceptional precision and reliability. PM technology excels in producing the tiny gears found in watch movements, where components often measure just a few millimeters in diameter. These gears must maintain precise tolerances over millions of cycles while resisting wear and environmental factors.

Powder metallurgy offers several advantages for watch gear production:

- Consistent Quality: Each gear produced is virtually identical, ensuring reliable performance across production runs

- Complex Geometries: Intricate tooth profiles and integrated features can be formed in a single operation

- Material Efficiency: Near-net-shape production minimizes material waste, important when working with precious metals

- Surface Finish: PM gears can achieve smooth surface finishes suitable for low-friction operation

Applications in Lock Manufacturing

Security locks require gears that combine strength, durability, and precise engagement. Whether in residential deadbolts, commercial access systems, or high-security safes, PM gears provide the reliability that lock manufacturers demand.

Key benefits for lock applications include:

- Wear Resistance: PM gears can be engineered with self-lubricating properties through controlled porosity

- Strength: Heat-treated PM gears match or exceed the strength of machined components

- Cost Efficiency: High-volume production capabilities make PM ideal for standardized lock components

- Security Features: Complex internal geometries can be incorporated to prevent tampering

Advantages of Powder Metallurgy for Gear Manufacturing

Economic Benefits

Technical Advantages

Environmental Considerations

Quality Control and Standards

Modern PM gear manufacturing employs sophisticated quality control measures to ensure consistent performance. These include:

- Dimensional Inspection: Coordinate measuring machines (CMM) and optical comparators verify gear geometry

- Metallographic Analysis: Microscopic examination ensures proper sintering and material structure

- Functional Testing: Gear mesh testing confirms smooth operation and proper tooth engagement

- Statistical Process Control: Continuous monitoring maintains process capability and product consistency

At Eurobalt, our gears meet international standards including ISO 5755 (PM gears), AGMA specifications for gear quality, and customer-specific requirements for critical applications.

Future Developments

The powder metallurgy industry continues to evolve with advances in:

- Additive Manufacturing Integration: Combining PM with 3D printing for prototype development

- Advanced Materials: Development of new alloy systems for enhanced performance

- Smart Manufacturing: Implementation of Industry 4.0 concepts for improved process control

- Nano-powder Technology: Ultra-fine powders enabling even higher precision and new material properties

Powder metallurgy has revolutionized the production of precision gears for demanding applications. From the intricate mechanisms of luxury timepieces to the robust security of modern locks, PM gears deliver the perfect combination of precision, performance, and cost-effectiveness.

At Eurobalt, we continue to invest in advancing our PM capabilities to meet the evolving needs of our customers. Whether you require thousands of identical watch gears or specialized components for security applications, our powder metallurgy expertise ensures that every gear meets the highest standards of quality and performance.

For more information about our powder metallurgy gear manufacturing capabilities, or to discuss your specific requirements, please contact our technical team. We’re ready to help you leverage the advantages of PM technology for your next project.