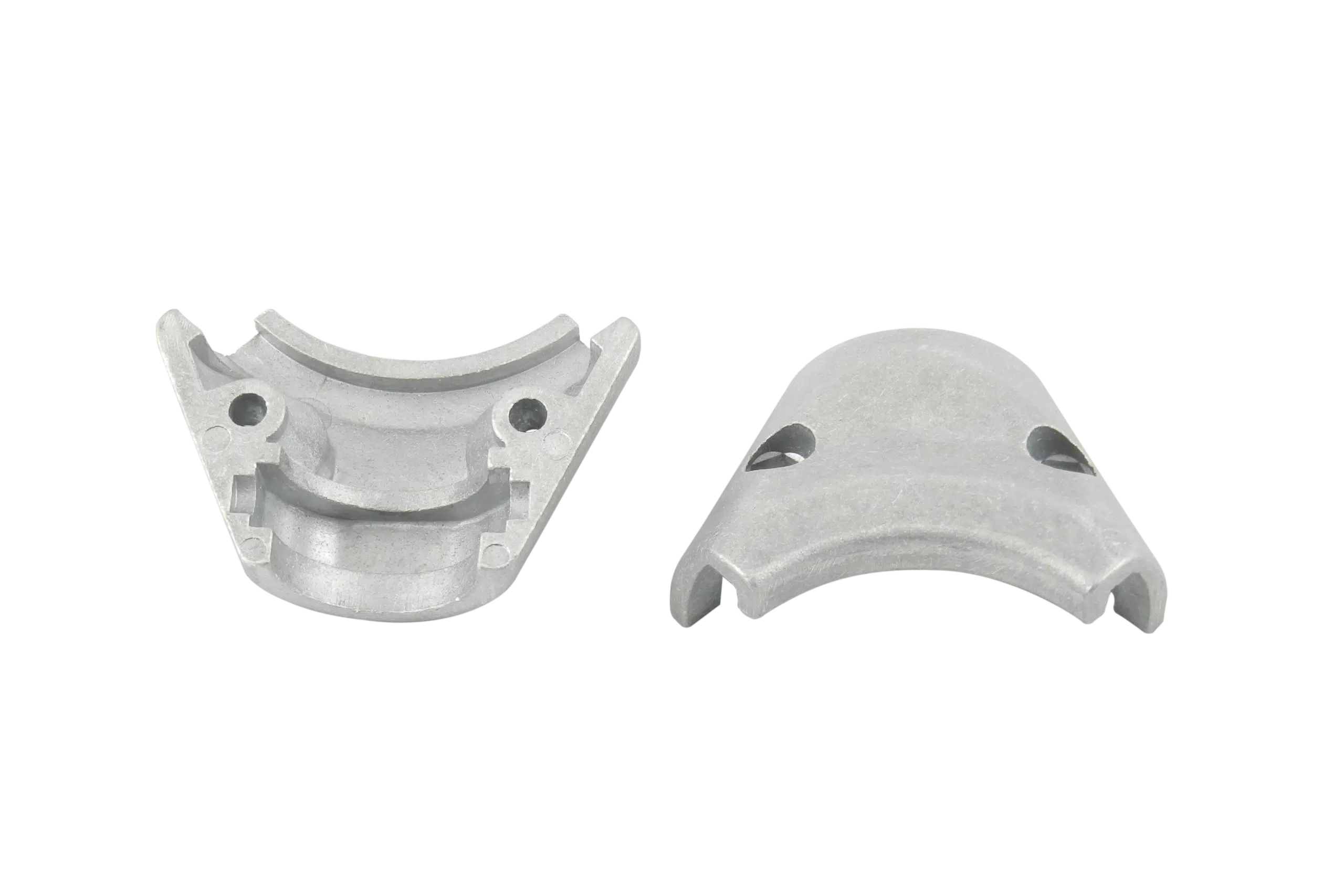

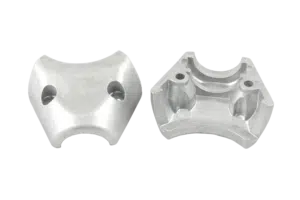

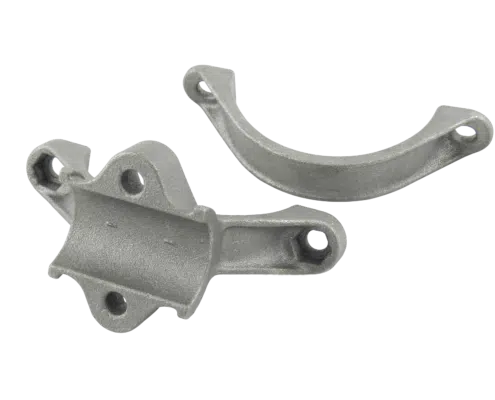

Casting

Casting is a manufacturing process in which molten metal, is poured into a specially designed mould and then allowed to solidify. The solidified part is known as casting. After solidification, the workpiece is then removed from the die to undergo different finishing treatments processes or for use as a final product. Casting methods are typically used to create very complicated or detailed solid shapes, heavy equipment and cast products are wildly used in different applications, including automotive components, aerospace parts, electronics, mechanical devices, and construction supplies.

Different types of casting and the casting process

Application of casting

- Transport: Automobile, aerospace, railways and shipping.

- Heavy Equipment: Construction, farming and mining.

- Machine Tools: Machining, casting, plastics moulding, forging, extrusion and forming.

- Plant Machinery: Chemical, petroleum, paper, sugar, textile, steel and thermal plants.

Eurobalt engineering makes use of die casting to produce different parts with different metal materials according to OEM customers, not limited zinc and aluminum metal materials. We take great pride in our ability to reduce the manufacturing and tooling costs, also in our high-quality control management system.