Telescopic Hydraulic Cylinders – Application and Possibilities

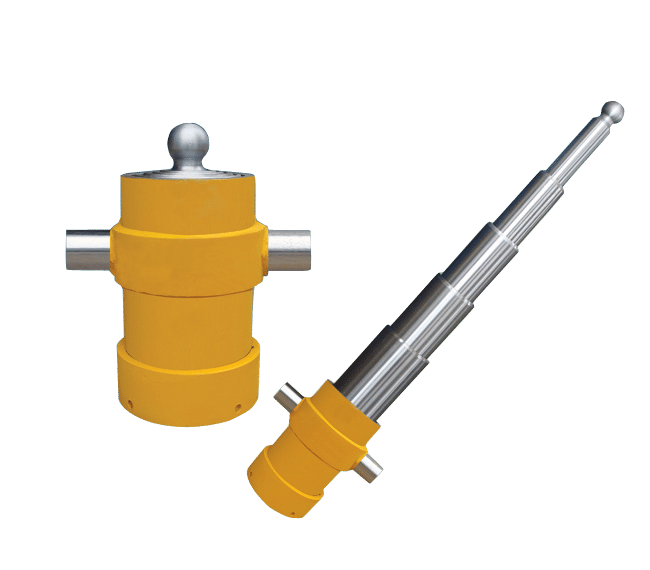

When a standard hydraulic cylinder‘s stroke does not suffice for the required task, a telescopic hydraulic cylinder is utilized. The telescopic cylinder is layered in stages, allowing the piston’s effect to expand over multiple barrels that fit snugly in a small primary sleeve.

Since most telescopic hydraulic cylinders are assembled within a sleeve, which is approximately 20% of the entire working length, they provide a superior working stroke. When a conventional single-rod hydraulic cylinder is not suitable due to limited space, a telescopic hydraulic cylinder is utilized.

This type of cylinder operates similarly to single- and double-acting hydraulic cylinders. The notable difference between them is that in telescopic cylinders, the piston or barrel is nested in a compact housing along with other tubes that extend simultaneously with the extension of the piston or primary barrel.

Manufacturing of Telescopic Hydraulic Cylinder at Eurobalt®

The manufacturing of telescopic hydraulic cylinders takes place on our premises. We manufacture all the components and then assemble them after all the parts have gone through a rigorous testing and screening process.

While we provide fully assembled telescopic hydraulic cylinders, our customers have the luxury of ordering specific parts for their own assembly process. Let’s take a look at how parts of telescopic hydraulic cylinders are manufactured and then assembled.

Manufacturing Parts for Telescopic Hydraulic Cylinders

The housing of a telescopic hydraulic cylinder is the outer casing that stores the nested barrels used during the expansion. For the manufacturing of housings, we utilize machining to get the required circular shape.

The metal type and length specified by the clients are used when producing the housing. Since it is the most essential part of a telescopic hydraulic cylinder, it is produced in our factory in the first place. When it comes to a regular piston, the piston, or the main tube, is also machined with the possibility of sintering.

The rods are made with certified metals and are machined to take the perfect shape. Holes are also made in the sleeves for the flow of oil or pressurized liquid.

For hydraulic heads and glands, production is done through the sintering process. Sintering helps to reduce the wastage of material. Then, to finish off the process, machining is used to remove kinks and some deformities. The end caps of telescopic hydraulic cylinders also undergo a similar process.

Assembly of Telescopic Hydraulic Cylinders

Assembly of telescopic hydraulic cylinders is also done in our factory. We can supply singular parts as well as provide ready-made cylinders for our customers. During the assembly process, quality control is done with vigour by our experienced technicians who have years of experience assembling telescopic hydraulic cylinders.

We can manufacture both single- and double-acting telescopic hydraulic cylinders. Single-acting is a simpler process, but the quality control and attention to details are not let up for a second.

A double-acting telescopic hydraulic cylinder is a complex piece of machinery that requires a lot of attention, as there are numerous moving and essential parts in it. Since our employees are experienced in the assembly of both types of cylinders, we are best suited to satisfy your needs.

Application of Telescopic Hydraulic Cylinder

For most equipment requiring hydraulic cylinders, a single rod system will do as they are less complex and extremely reliable. But there are certain situations where, depending on the application, one needs to switch to telescopic hydraulic cylinders.

With a telescopic hydraulic cylinder, there are more strokes in a compact size, and this long stroke combined with the size comes in handy when there is a small surface area to work within a vehicle or machinery.

While single-rod hydraulic cylinders can be utilized in most cases, here are some applications of telescopic hydraulic cylinders:

Possibilities with Eurobalt®

At Eurobalt, we take all of our customers’ wishes in stride. Our production line is equipped to handle most of our customers’ customization requests. Whether it is the length of the telescopic hydraulic cylinder or the material of the seals used, there are a variety of options that we make available to our partners.

In a competitive market, we have to offer competitive prices and also the best quality of the product. Keeping all this in mind, we still offer different features according to the needs of our customers. Customization and availability are two of our strongest points, so the possibilities are endless with Eurobalt®.