Eurobalt Engineering for Your Sintering and Tooling Needs

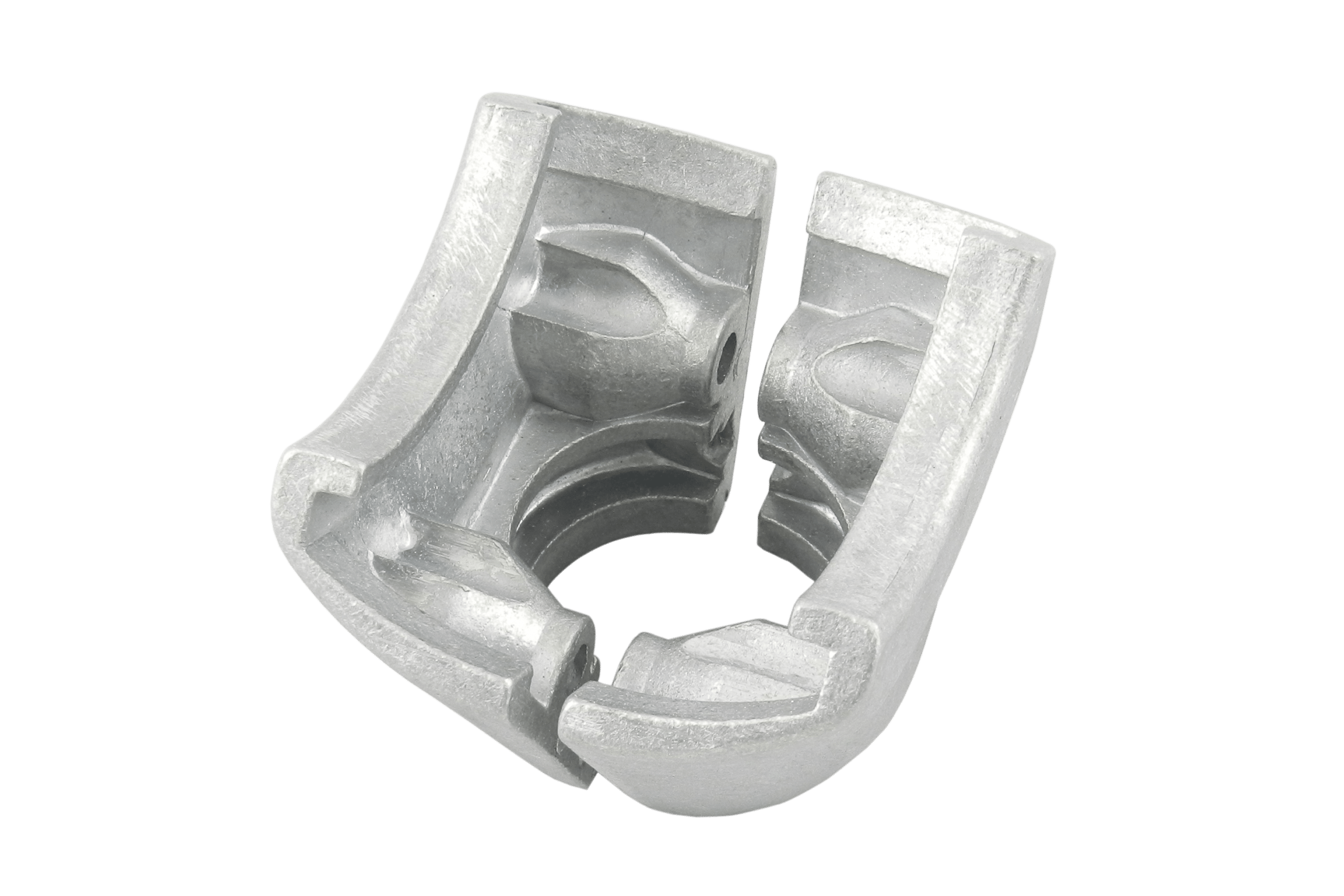

Powder metallurgy is an additive manufacturing process where fine metal parts are compressed under high pressure and later sintered to fuse the pressed materials together. The process requires one vital component and it is called a die or tooling, which is responsible for giving metal parts the required shape.

While press and sintering machines are all important for the powder metallurgy manufacturing method, the process is moot without the help of dies that give powders the required shape. The die is essential, since it can make or break your whole manufacturing process.

A tooling done right will be a boon to the whole manufacturing process and at Eurobalt Engineering we do our own production and toolings. So, we would like to explain some things that go into the manufacturing of a good tooling for the powder metallurgy process.

For Your Tooling, Powder Metallurgy, and Sintering Needs – Eurobalt Engineering

We have been manufacturing sintered parts for our partners all over Europe for a long time now. The reason our partners have chosen us is that we have extensive knowledge in production and we do all our production in-house, including toolings.

When our clients need to use the powder metallurgy process for their production needs, we make new tooling according to their requirements. Our own manufacturing also allows us to handle any issues that may occur during production swiftly.

The right tooling eases the burden of mass production and, since we do everything on our own, it is even easier for us. So, get in touch with us via email or phone, tell us your complex problems and we will tell you how we can ease your burden.