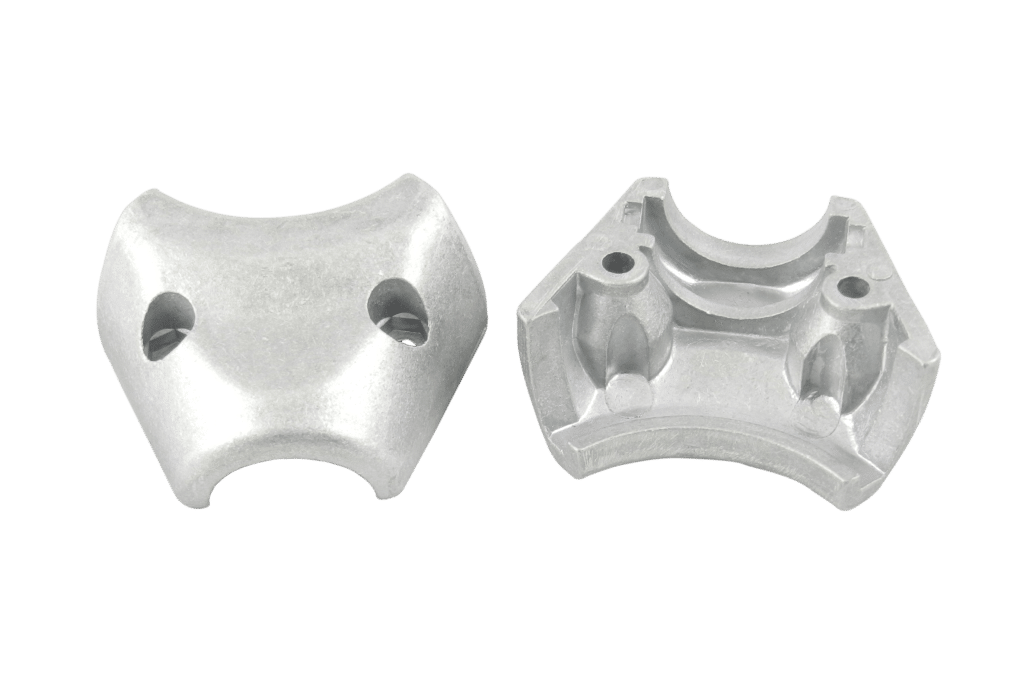

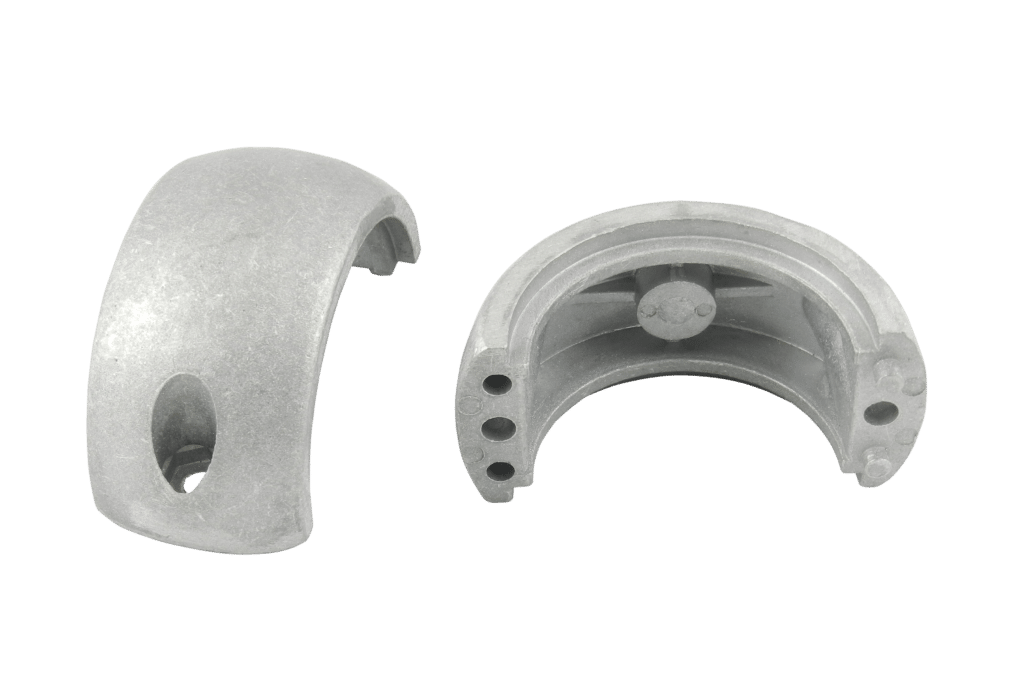

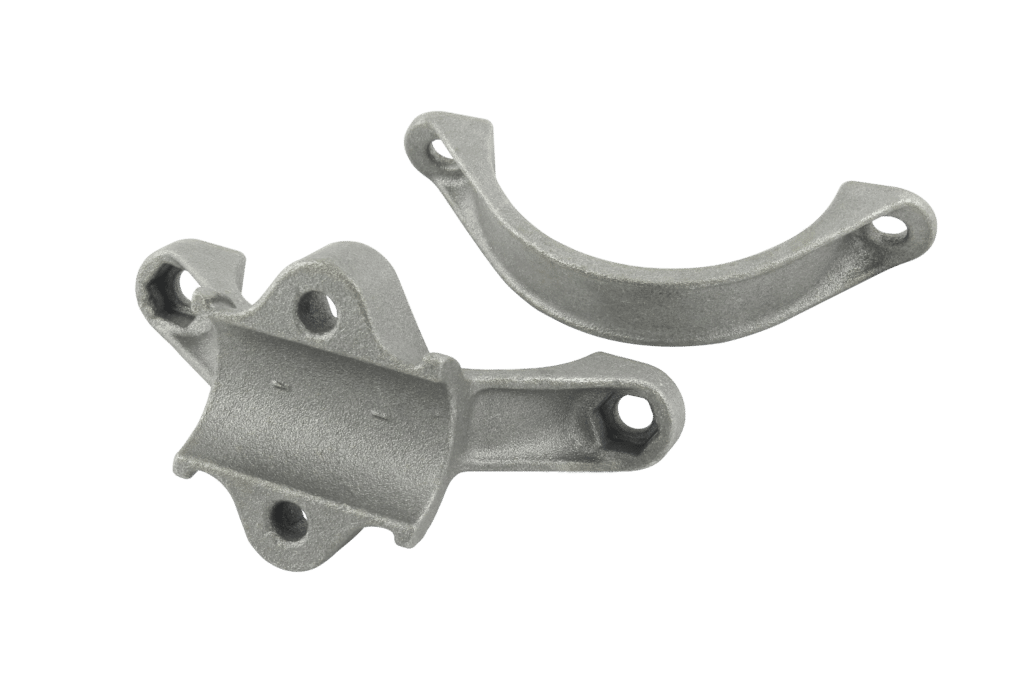

Cleaning and Deburring of Casted Parts

Deburring is the process of removing excess material on the surface of manufactured parts, whether ferrous or non-ferrous, which can pose handling hazards or compromise the structural integrity of the material. Usually, deburring occurs after machining, although the casting process also exposes surface imperfections that require deburring.

It is a pre-finishing process that involves subjecting the manufactured part to various methods of removing deformities once die casting is completed.Deburring can be a time-consuming process, prompting many companies to outsource or altogether skip it. However, there is a crucial reason why deburring remains vital to manufacturing die-cast parts.

Why is Deburring Necessary?

While some manufacturers may try to avoid deburring due to its associated costs and time requirements, we at Eurobalt Engineering ensure that the parts you receive are nearly flawless. Additionally, we recognize and prioritize the significance of effective deburring. This process is essential for the durability and longevity of the finished product. Below, we present some key reasons why deburring is a necessary step in the manufacturing process.

Types of Deburring Techniques

There are five distinct techniques for deburring casted parts that are widely utilized, each with its own specialized area. All five are capable of delivering exceptional deburring outcomes, and thus, your selection should be based on your preference for one of the five techniques.

Some Ways to Avoid Deburring

Deburring is a time-consuming process that can result in loss of valuable time and manpower when working on the same manufactured tool. Although deburring is sometimes unavoidable, there are manufacturing techniques available to minimize burrs. Here are some ways to reduce burr creation and avoid deburring:

Eurobalt Provides Cleaned and Deburred Casted Parts

We specialize in die casting as one of the primary operations of our metalworking company. We manufacture die-casted products in different shapes and sizes, and based on client requirements, we offer surface finishing, coating, and painting services.

Furthermore, our factory is equipped with deburring machines to ensure that the die-casted parts are finished flawlessly. We provide a variety of techniques to our clients, and choose the best possible solution based on the materials used, resulting in near-perfect outcomes.

Working with us, you will have access to a comprehensive range of services including manufacturing, pre-finishing, and finishing all readily available under one roof. Outsourcing won’t be necessary as we manage every step of the production process for you. Simply send us your drawings, and we’ll take care of the rest.