Manufacturing of Large Metal Shafts: Technologies and Applications in Modern Industry

Large metal shafts are critical components in heavy industry, energy, shipbuilding, and oil and gas sectors. These massive parts, reaching several meters in length and weighing tons, require a special approach to production and processing. This article examines modern methods of manufacturing large-scale shafts, technological features, and application areas.

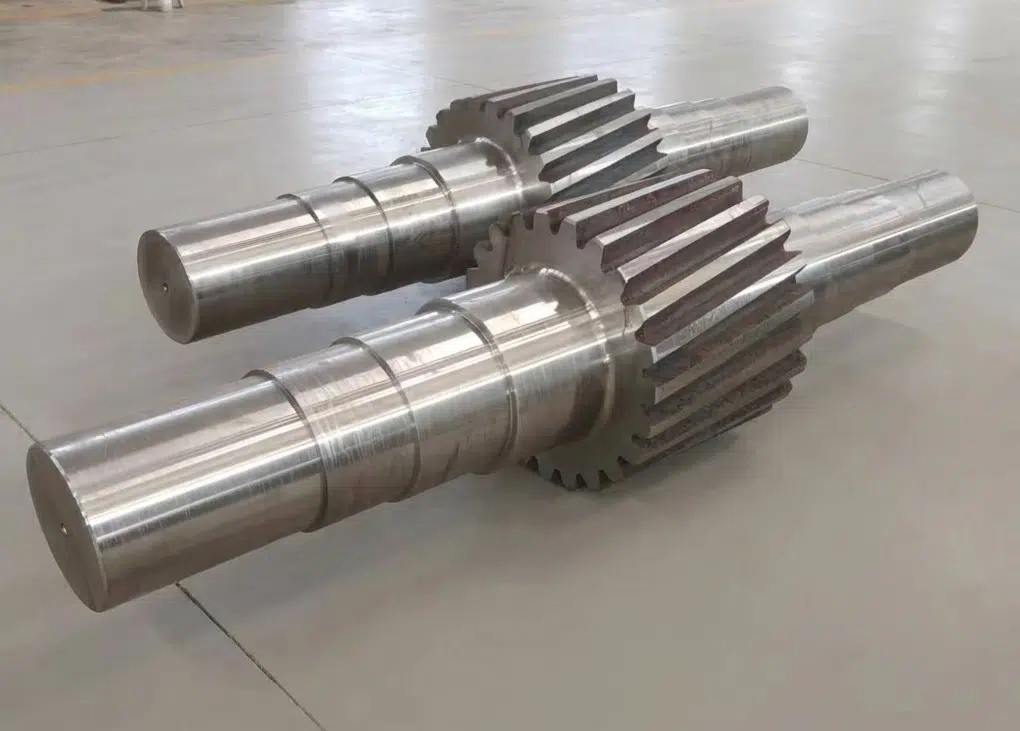

What Are Industrial Shafts and Their Classification

An industrial shaft is a rotating mechanical component designed to transmit torque and support rotating elements. Large shafts are classified according to several parameters:

By dimensions

By purpose

Main Production Methods

1. Forging and Stamping

Forging remains the primary method for producing large-scale shafts. The process includes:

- Open-die forging — shaping the workpiece under hammer or press without using special dies. Enables production of shafts with diameters up to 2000 mm and lengths up to 20 meters.

- Radial forging — specialized process where four or more dies simultaneously compress the workpiece, ensuring uniform metal structure and high dimensional accuracy (tolerances ±0.5 mm on diameter).

Forging temperature regime for carbon steels: 1150-850°C, for alloy steels: 1200-900°C.

2. Casting with Subsequent Mechanical Processing

For shafts of complex configuration, casting is applied:

- Centrifugal casting — ensures dense structure without pores and cavities, particularly effective for hollow shafts

- Sand casting — economical method for single-piece production

- Die casting — for serial production of medium-sized shafts

After casting, heat treatment is mandatory to relieve internal stresses and improve mechanical properties.

3. Powder Metallurgy for Special Applications

Although powder metallurgy is traditionally used for small parts, modern HIP (Hot Isostatic Pressing) technologies enable creation of large blanks for special-purpose shafts:

- Shafts from heat-resistant alloys for gas turbines

- Composite shafts with gradient properties

- Shafts from difficult-to-machine materials

HIP processing parameters: pressure 100-200 MPa, temperature 1000-1200°C, holding time 2-4 hours.

Mechanical Processing of Large Shafts

Turning

Processing of large-scale shafts requires specialized equipment:

- Heavy lathes with processing lengths up to 30 meters

- Steady rest support systems to prevent deflection

- Cutting conditions: speed 30-80 m/min, feed 0.3-1.2 mm/rev, cutting depth up to 10 mm per pass

Grinding

Finishing operations include:

- External cylindrical grinding — achieving accuracy up to IT6 and roughness Ra 0.4-0.8 μm

- Superfinishing — for particularly critical surfaces (Ra up to 0.1 μm)

Balancing

Dynamic balancing is critical for high-speed shafts:

- Permissible unbalance for turbine shafts: class G2.5 per ISO 1940

- Balancing methods: material removal, addition of balance weights

Quality Control

Non-Destructive Testing

- Ultrasonic testing — detection of internal defects from 2 mm size

- Magnetic particle testing — detection of surface cracks

- X-ray testing — for critical shaft zones

Geometry Measurement

- Laser measurement systems with accuracy ±0.01 mm

- Coordinate measuring machines for complex profile control

- Runout checking: radial ≤0.05 mm, axial ≤0.03 mm for precision shafts

Application Areas and Examples

Energy Sector

Turbogenerator shafts for power plants:

- Length: 15-25 meters

- Diameter: 800-1200 mm

- Material: alloy steel 25Х1М1Ф, 20Х3МВФ

- Operating speed: 3000 rpm (50 Hz) or 3600 rpm (60 Hz)

Shipbuilding

Propeller shafts for large tonnage vessels:

- Length: up to 30 meters

- Diameter: 600-1000 mm

- Material: steel with anti-corrosion treatment

- Feature: bronze bushing cladding in seawater contact zone

Metallurgy

Rolling mill shafts:

- Work rolls: diameter 400-800 mm, surface hardness 55-65 HRC

- Backup rolls: diameter 1200-2000 mm

- Material: high-chromium steels, cast irons with chilled layer

Innovative Technologies

Additive Manufacturing

Modern metal 3D printing methods open new possibilities:

- Creation of hollow shafts with internal cooling channels

- Local hardening of critical zones

- Repair and restoration of worn areas

Composite Shafts

Hybrid metal-composite constructions:

- Weight reduction by 30-40%

- Increased damping capacity

- Application in aerospace industry

Economic Aspects

Production costs for large-scale shafts consist of:

- Material: 30-40% (for special alloys up to 60%)

- Mechanical processing: 35-45%

- Heat treatment: 10-15%

- Quality control: 10-15%

Manufacturing time: from 3 months for standard shafts to 12-18 months for unique items.

The production of large metal shafts represents a complex technological process requiring a combination of traditional and innovative processing methods. Modern technologies, including precision forging, HIP processing, and additive manufacturing, enable creation of shafts with improved operational characteristics for the most demanding applications.

Companies specializing in precision metalworking and possessing the full spectrum of technologies — from powder metallurgy to finishing operations — can offer optimal solutions for shaft production of any complexity, ensuring reliability of critical equipment across various industrial sectors.