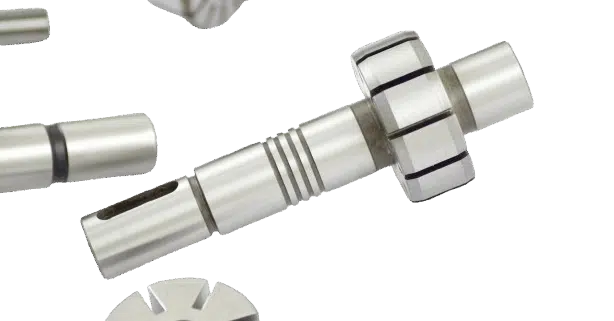

Manufacture of rotors and shafts by powder metallurgy technology

Eurobalt Production Success

Series of rotors and shafts manufactured using powder metallurgy

Eurobalt has successfully completed the delivery of a pilot-industrial batch of rotors and shafts for a major European manufacturer of special equipment. The key to success was powder metallurgy (PM) with subsequent sintering — a technology that opens new horizons for precision, strength and cost-effectiveness in modern mechanical engineering.

Production Results Demonstration

Advantages of Powder Metallurgy

🔧 Minimal Waste

The product is formed almost to the final contour, reducing metal losses to 3-5% compared to conventional processing methods.

📏 High Precision

Achievable accuracy IT8-IT9 directly after sintering, minimizing the need for mechanical finishing.

⚡ Controlled Properties

Selection of powder composition allows obtaining required hardness, wear resistance and corrosion resistance.

💰 Economic Efficiency

For medium and large series, savings reach 30-40% of total production costs.

Manufacturing Process

Powder Mix Preparation

Using alloy steels with particle size less than 80 microns and adding 0.6% lubricant to ensure optimal flowability.

Cold Pressing

Forming blanks under pressure 400-600 MPa achieving density of 6.5-6.8 g/cm³.

High-Temperature Sintering

Processing at temperature 1120-1150°C in controlled N₂-H₂ atmosphere for 60-90 minutes.

Calibration and Finishing

Re-pressing to improve accuracy and machining of critical surfaces to Ra ≤0.8 μm.

Technical Specifications

| Parameter | Value | Note |

|---|---|---|

| Material | Sintered steel with 2% nickel content | Enhanced strength and toughness |

| Density | 6.9-7.0 g/cm³ | 95-97% of theoretical density |

| Hardness | 25-30 HRC | Optimal for most applications |

| Manufacturing accuracy | IT8-IT9 | Achievable directly after sintering |

| Surface roughness | Ra 2.5-3.2 μm | After sintering, before finishing |

| Maximum diameter | Up to 120 mm | Limitation for complex parts |

Achieved Results

📈 Cost Reduction

- Material waste reduction by 40-50%

- Labor cost reduction by 30-40%

- Energy consumption reduction by 20-25%

⚙️ Operational Improvements

- Vibration reduction by 10-15%

- Service life increase by 15-20%

- Energy efficiency improvement by 3-5%

⏱️ Delivery Cycle Reduction

Full production cycle reduced to 6 weeks versus 12 weeks for conventional forging with machining.

🌱 Environmental Impact

For each ton of production, up to 400 kWh of energy and 150 kg CO₂ equivalent are saved.

Technology Applications

Powder metallurgy is optimal for:

- Complex geometry — internal keyways, oil channels, variable cross-sections

- Series production — from 1,000 units per year and higher

- High uniformity requirements — minimal variation in mechanical properties

- Combined materials — combination of steel and copper phases in one product

- Weight reduction — controlled porosity without strength loss

About Eurobalt Production Capabilities

Our company combines foundry, powder metallurgy and machining production within a single technological cluster in the Baltics. This allows us to provide a complete manufacturing cycle — from tooling design to finished product packaging.

🏭 Modern Equipment

Own fleet of presses with force up to 800 tons, horizontal sintering furnaces up to 1200°C

🔬 Quality Control

Metrology laboratory accredited to ISO 17025 standard

👥 Expertise

Team of engineers with over 15 years experience in powder metallurgy

📋 Flexibility

Capability to manufacture both prototypes and large series up to 500,000 parts per year

Ready to discuss your project?

Contact our engineers and learn how Eurobalt powder metallurgy technologies will help reduce costs and improve reliability of your rotors, shafts and other rotating parts.

📧 info@eurobalt.net | 🌐 www.eurobalt.net

We will respond within 24 hours