MIM Technology in Lock Component Manufacturing: Precision and Security

The lock and access control systems industry places exceptional demands on the accuracy, durability, and dimensional stability of components, which directly affects the reliability and tamper resistance of products. Metal Injection Molding (MIM) technology gives lock manufacturers a competitive advantage: mass production of complex, miniature parts with high density, surface finish, and repeatability without increasing unit cost.

Why MIM is Ideal for Locks

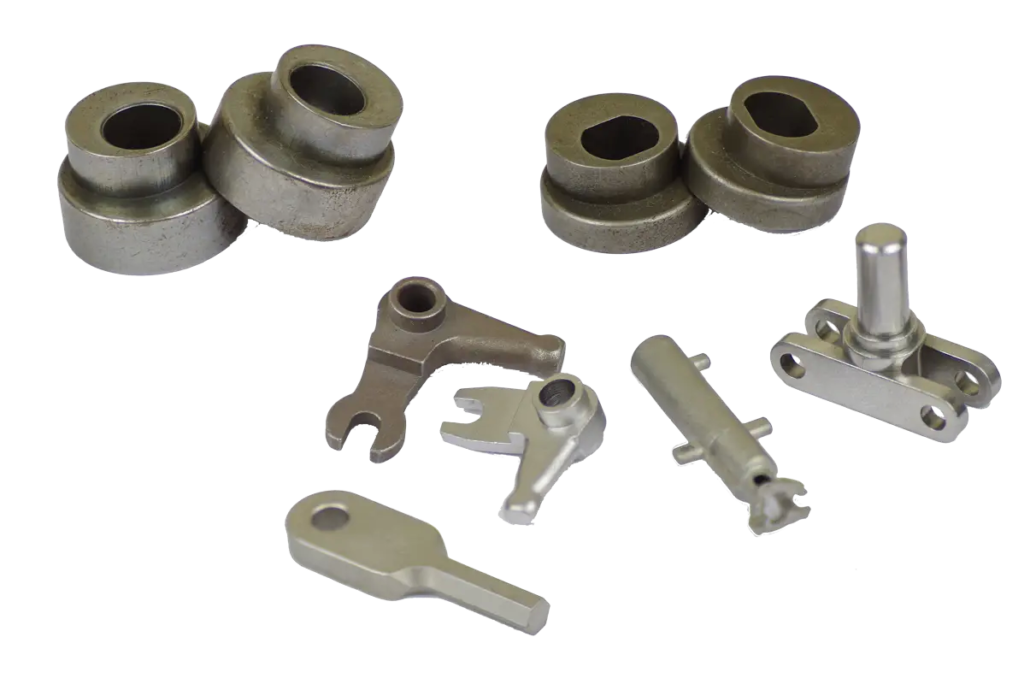

Modern locks consist of numerous small-sized parts with complex geometry: pins, drivers, tumblers, sidebar pins, discs, spring-loaded assemblies, guides, and micro-housings. At these dimensions, traditional machining and die casting are either expensive or limit accuracy and geometric complexity.

MIM consistently provides thin walls from ~0.3-0.35 mm, accuracy to ±0.3-0.5%, and good surface finish, which is critical for smooth element movement and proper fits.

By forming complex internal cavities in a single cycle, the need for deep drilling and multi-stage finishing is eliminated, while batch repeatability simplifies spare part interchangeability and service.

Key Components Optimal for MIM

Materials and Properties

For internal and external assemblies, stainless steels are available (e.g., 316L for corrosion resistance and 17-4PH for high strength), as well as low-alloy steels for optimal price-performance balance.

For special requirements, non-magnetic and wear-resistant alloys are used: non-magnetic for protection against magnetic tampering, hard alloys for friction pairs and impact loads.

MIM part density reaches 95-99% of theoretical; after heat treatment and finishing operations, strength, hardness, and dimensional stability are ensured per specifications.

Economic Advantages of MIM

Accuracy, Surface Finish, and Tolerances

The basic accuracy level for most geometries is up to ±0.3-0.5% by dimension, which for small sizes gives deviations in hundredths of a millimeter.

Standard surface finish reduces the need for grinding and polishing of sliding elements, facilitating pin movement and resistance to jamming.

Design accounts for sintering shrinkage (typically 14-20% depending on material and feedstock), with technological allowances and draft angles incorporated.

Quality Control and Standards

The production cycle includes feedstock preparation, injection, debinding (thermal/solvent/catalytic), sintering in controlled atmosphere, and post-processing.

Output employs coordinate measuring machines (CMM) for dimensional control, hardness and strength testing, density verification, and functional tests within lock assemblies.

Finished components can meet ANSI/BHMA requirements and corporate specifications of security system manufacturers, including life cycle and environmental testing.

Innovations and the Future of MIM in Locks

Combining MIM with rapid prototyping (3D printing for fit/kinematics verification) accelerates the launch of new lock models and modular platforms.

Additive manufacturing of tooling and cooled mold inserts improves geometric stability, reduces cycle time, and expands the range of producible microgeometries.

The trend toward biometric and networked locks increases demand for compact MIM housings, kinematic pairs, and shielding solutions compatible with electronics and EMC requirements.

Environmental Aspects

Minimal waste and runner recycling reduce the carbon footprint compared to cutting and multi-stage machining.

Sintering optimization (atmosphere, temperature profiles) reduces energy consumption while maintaining required density and mechanical properties.

Reducing the number of processing operations simplifies the production chain and reduces tool wear.

MIM Design Recommendations

Partnership Benefits with Eurobalt

Eurobalt specializes in powder metallurgy and MIM technologies for serial production of precision lock components.

The team assists at the DFM/DFMIM stage: adapts design documentation for shrinkage, selects feedstock and sintering modes, reduces post-operation needs.

Production facilities maintain stable batch quality from pilot series to million-unit runs with complete measurement and test protocol packages.

MIM radically increases the efficiency of producing miniature, precise, and complex lock parts – from pins and sidebar pins to cylinder housings and smart lock assemblies.

The combination of high precision, density, surface finish, and design freedom makes the technology optimal for mass series with strict security requirements.

Eurobalt is ready to engage at the idea stage and bring the product to serial status, providing predictable cost, quality control, and supply logistics.

For consultation and project evaluation, send drawings/STEP models and expected production volumes; specialists will offer DFM recommendations, material selection, and approximate batch economics.