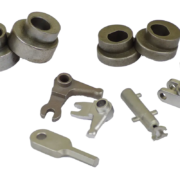

Precision Gear Manufacturing Through Powder Metallurgy

Eurobalt specializes in precision powder metallurgy components for various industries. With state-of-the-art manufacturing facilities and decades of experience, we deliver quality parts that meet the most demanding specifications.